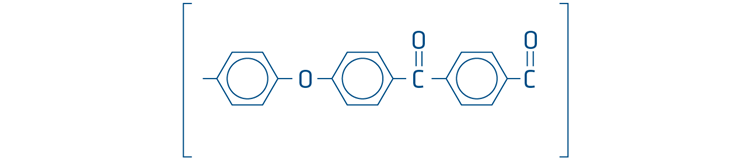

The group of polyaryletherketones (PAEK) is characterised by exceptional mechanical, thermal and chemical properties and is therefore used in numerous industries and applications. The plastics in this group consist of chemical bonds with ether and ketone groups, which are linked via aryl groups.

The more ketone groups are present in a structure, the more flexible the material tends to be. In addition to the frequently used PEEK plastic from this group, the variation of PEKK is likewise recommended for certain applications. It is also inherently flame retardant and offers good mechanical properties but has a lower degree of crystallinity. Accordingly, PEKK is considered easier to print because, among other things, it does not require such a high build chamber temperature, which makes it particularly attractive for 3D printing.

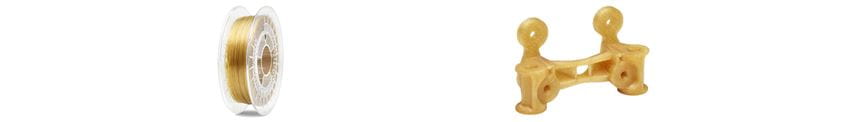

At Ensinger, we offer PEKK filaments that can be 3D printed.

The properties of PEKK polymer are very similar to those of PEEK. Differences can be found, for example, in the melting and glass transition temperature, due to the different amount of ether and ketone groups.

The outstanding properties of PEKK include: