Polyphenylsulphone (PPSU) has a high dimensional stability and is therefore ideally suited for CNC machining. Due to its very good mechanical and chemical properties, PPSU material is often the perfect solution in medical technology and is increasingly displacing the metals that were previously common. Due to its very good machinability, PPSU turning and PPSU milling is the fastest and most efficient production method for the quantities commonly used in the medical and biopharmaceutical industries.

Ensinger is a specialist in the certified production of PPSU machined parts in accordance with ISO 13485. Together with our trusted partners, we have developed product lines that are market leaders in terms of quality in the medical industry.

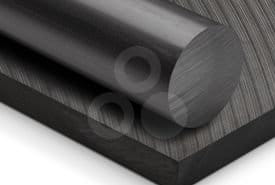

With our many years of experience and outstanding quality, we have firmly established ourselves in the market for PPSU machining. The basis of our PPSU machined parts are usually semi-finished PPSU products (PPSU rods, plates and tubes) manufactured by Ensinger. However, industrial profiles or injection moulded parts can also be further machined. Such geometrically close blanks have the advantage that both material costs and processing times can be significantly saved.

Please contact us for more information about our PPSU machining capabilities at Ensinger.