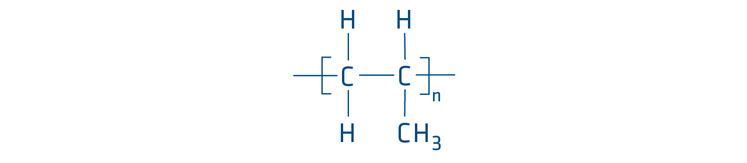

Polypropylene (PP) plastic is a semi crystalline thermoplastic produced by catalytic polymerisation of propylene and belongs to the more broadly characterised group of materials known as polyolefins. PP materials are universally standard plastics with well balanced properties that provide excellent chemical resistance, high purity, low water absorption and good electrical insulating properties. In addition, Polypropylene material is lightweight, conductive and weldable.

Modifications of PP plastic materials are produced by Ensinger under the brand names TECAFINE PP and TECAPRO MT (for medical applications). Semi-finished products made of polypropylene plastic are manufactured by Ensinger for further processing in the following forms, among others:

PP polymer is manufactured by Ensinger's various processes for different industries, and thus complies with food safety regulations and medical safety requirements. The manufacturing process for TECAPRO MT includes special heat-stabilising procedures to make it more autoclavable. The Ensinger TECAFINE and TECAPRO family offers the following polypropylene modifications:

The PP properties are: