Machining is the fastest and most economical way to produce a high precision finished plastic part, especially for small batches and series with medium quantities.

Ensinger has decades of experience in machining of engineering and high temperature plastics. Equipped with state-of-the-art technology in manufacturing and finishing, our excellently trained specialists produce precision parts with the tightest tolerances and outstanding surface quality.

Due to our broad portfolio of high-performance plastics, we primarily use our own stock shapes and injection-molded blanks for machining. This makes Ensinger an ideal and reliable partner, offering our customers security and flexibility at the same time!

We leverage the expertise within the Ensinger Group network to deliver the best solutions for each customer. Together with technicians and engineers, our sales department provides support in the selection of materials, component design and the structural design of the finished part. Thanks to flexible and fast cooperation across different stages of plastic processing, we have an exemplary range of technologies at our disposal to achieve the optimum result for you.

Ensinger not only offers machining and all the services around it - you also benefit from the concentrated expertise of the entire Ensinger Group. From compounds to semi-finished products in the form of plates, rods and tubes, or even processed into injection molded blanks, we supply your finished part from a single source.

More than 100 modifications of plastics are available to meet the most demanding requirements.

Ensinger was one of the first companies to machine high-temperature plastics. Since the opening of our first machining facility in 1980, a great deal of knowledge has been accumulated around plastic machining, new locations have been established and industry standards have been implemented. As a result, we can also draw on extensive experience in specialised manufacturing, such as the production of implants made of PEEK Optima®.

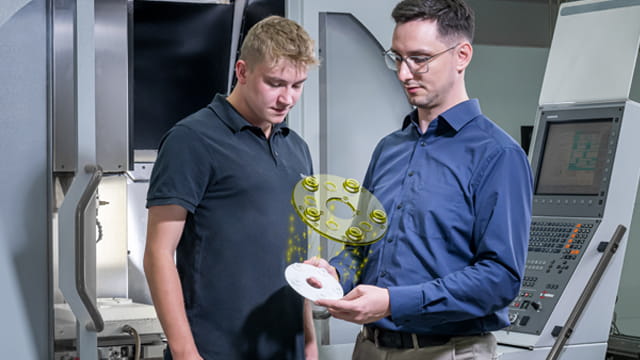

Our greatest assets are our employees. Through our own training, we create the foundation for the future and can thus pass on knowledge in a targeted manner and develop new manufacturing strategies. As with a successful football team, the mix of older, experienced employees and young, inquisitive colleagues is crucial.

This short guiding text reflects Ensinger Machined Parts' recipe for success. Because we always focus on the optimum technical and economic solution for our customers.

Batch traceability is an elementary component in the process chain of every single product at Ensinger. This is ensured by consistently complete documentation during the individual process steps from the raw material to the finished product. Another major advantage of Ensinger is that we process a high percentage of semi-finished products from our own extrusion (One-stop shop).

We offer a large base of qualified equipment and validated processes. Of course, we validate further necessary processes together with you. We are happy to advise you on this if no specifications exist or changes are necessary to obtain efficient and safe processes.

In our quality control we have extensive testing and measuring procedures. Classic gauges are as much a part of our portfolio as modern tactile coordinate measuring machines and optical measuring systems. In order to ensure constant monitoring of the manufacturing process, our qualified personnel makes detailed self-inspections during the process. Thus, the quality of the products is continuously checked and ensured during the manufacturing process.

Visual inspections during and after processing can also be realised under a microscope in order to exclude smallest damages or material defects.

In addition, we perform special functional tests (such as leak testing) or a check of non-visible factors upon request. In laboratory tests (at our long-term partner laboratories), products can be tested for cytotoxicity, TOC, THC or bioburden, for example.

The quality requirements for products and the demands on a quality management system are constantly increasing. Ensinger sees these requirements as an opportunity to constantly develop further. We meet numerous requirements, which are regularly monitored by our customers and (re)certified by the relevant inspection bodies.

Our long value chain does not end with the machined finished part. Ensinger has an extensive portfolio of additional services that surround and complement the actual machining process. From geometry-related waterjet cutting to surface treatment or cleaning, assembly and packaging in a clean room, we offer you numerous advantages.

Thanks to Ensinger's large and modern machine park, we can offer our partners security not only in terms of quality, but also in terms of general availability. Our worldwide locations offer additional security of supply in the event of global events or disasters, and at the same time provide customer proximity - think global and act local!

Thanks to our exemplary vertical range of manufacture, we offer numerous solutions from development to series products for a wide range of industries. This is one of the reasons why numerous companies have trusted us as a partner for many years.

The Ensinger Group has a long and extensive experience in machining in the aerospace industry. As the first PEEK transformer accredited by Airbus, we guarantee complete traceability of all machined parts with the supply of an ABS certificate.

The complex machined parts for the aerospace industry meet precise standards for tolerances and surface finish.

The major trends in the medical industry such as ageing patients and their mobility needs, as well as younger peoples' desire for a pain-free life, are resulting in an increase in surgical procedures as well as new treatment options. This is leading to greater prices and added cost pressures in the health systems and for medical product manufacturers.

The requirement to carry out unannounced audits, a tightening in clinical assessments, as well as additional testing procedures for certain medical products belonging to higher categories, are designed to enhance patient safety. This includes increased consideration of physiological safety even with short-term patient contacts, which leads to further emphasis on the product safety requirements.

For the manufacturers of medical products, this will mean the development of new, innovative products under the premises of product safety, patient benefits and cost control in future.

Ensinger helps to meet these requirements by supporting medical product manufacturers in creating product solutions with alternative, but tried and tested, materials and process technologies.

TECAPART is the calculation and ordering portal for the online manufacturing of plastic turned parts and CNC milled parts. With precise machining processes and high-quality standards, we machine first-class components from plastics such as PEEK, POM, or PA for various applications.

Thanks to modern technology and efficient processes, TECAPART enables faster and easier CNC machining than ever before. Simply upload your CAD model and your technical drawing to receive an immediate quote with delivery times and prices.

Whether it's CNC prototypes, small series, or large series – TECAPART is the perfect online platform for your CNC machining. Discover how we can effortlessly realise your CNC project.