The reinforcement of PTFE (chemically Polytetrafluoroethylene and colloquially referred to as Teflon®) with high performance polymers has many advantages compared to inorganic fillers. The most important properties are the excellent wear behavior without abrasion of the sliding partner. TECAPOWDER PI (based on P84® by Evonik) is an active filler in PTFE. This is shown by a highly increased creep resistance and a good mechanical bonding of the powder into the matrix.

The development of extremely fine powders lead to excellent surfaces of machined parts and skived films of these compounds.

TECAPOWDER PI filled PTFE (Teflon®) compounds outperform inorganic fillers in many ways. Many inorganic fillers have poor wear resistance, low elongations at high loadings and some fillers can be abrasive to the mating surface.

Application |

Replacement (type of compounds) |

Replaced material |

| Compressor parts piston and rider rings in bone dry applications | 85/15 and 80/20 |

PEEK composites, PTFE/bronze and PTFE/carbon/graphite compounds |

| Hydraulic seals, spring reinforced and others | 93/7 and 90/10 |

PTFE/carbon,PTFE/bronze and PTFE/EKONOL |

| Dynamic seals in air components | 80/20 and 85/15 P1 | PE/carbon compounds, rubber and PUR seals |

| Sealing bands for turbo charger | 80/20 |

PTFE/bronze and PTFE/bronze/MoS2 compounds |

| Sealing bans for shock absorbers | 75/20/5 |

Most other PTFE compounds tested |

| Sliding liner for multilayer bearings in automotive applications | 75/25 and 75/20/5, standard and paste types | PTFE/MoS2 and PTFE/lead compounds |

| Inner liner for push-pull cables | Proprietary paste compounds | PTFE/glass types, PTFE/PPS compounds |

| Guidance films for pistons and gliding components, esp. in weaving equipment | 85/15 with 1200 mesh, also with NPA additive | RULON |

| Lip-seals, packings, and spring-reinforced dynamic seals | 93 % PTFE / 7 % PI Powder |

| Rod packings, rider and piston rings in compressor applications, proved in "bone-dry" gas compressors as a piston and rider ring, skived films as gliding surfaces on several machinery elements, especially in textile equipment | 85 % PTFE / 15 % PI Powder |

| Bearings and gliding elements in highly stressed applications, sealing bands for rotating equipment in compressors and pumps | 80 % PTFE / 20 % PI Powder |

| Piston rings in pumps and compressors for dry gases, gliding elements in weaving machines | 75 % PTFE / 20 % PI Powder / 5 % Graphite |

| This composition for hot moulding is used in high load bearings and sealants in machining equipment and as guidance material in mechanical end uses | 60 % PTFE / 40 % PI Powder |

| Push-pull cable inner-liners to maintain long service life without any additional lubrication | 90 % PTFE / 10-15 % PI Powder |

The most important properties of TECAPOWDER PI filled PTFE (Teflon®) are excellent wear resistance at elevated temperatures, high elongation, and no abrasion of the sliding partner — all without the need for lubrication.

TECAPOWDER PI as an active filler in PTFE improves the mechanical properties of the PTFE. Blending 5-20 % loadings of TECAPOWDER PI VPD in PTFE creates wear resistant PTFE compounds that extend the performance envelope of standard PTFE materials especially at high pressures, velocities and temperatures. TECAPOWDER PI polyimide filled PTFE compounds are especially good running against soft mating surfaces.

Teflon® is a registered trademark of E.I. du Pont de Nemours and Company.

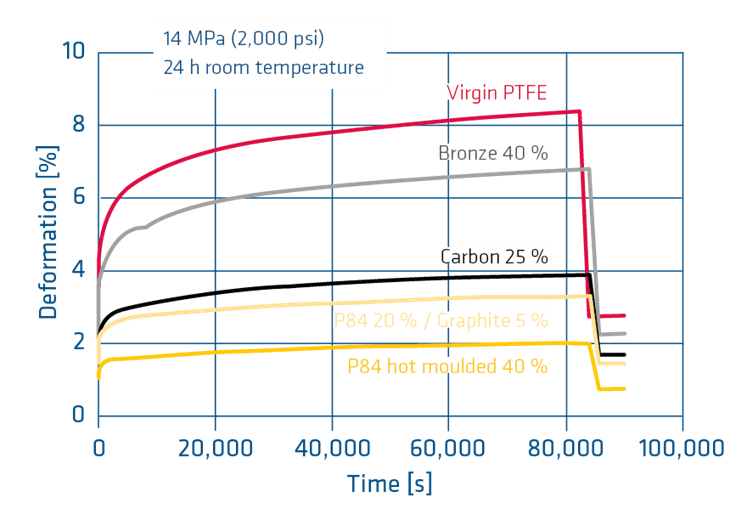

Creep under load at room temperature

Creep under load at room temperature

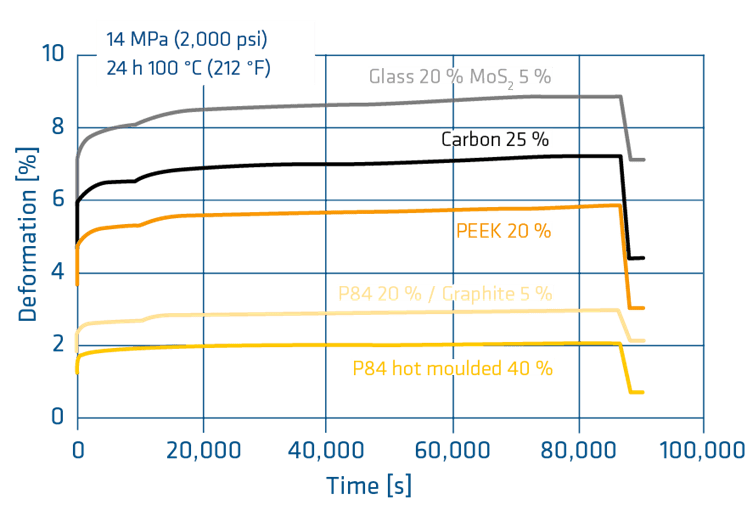

Creep under load at 100 °C (212 °F)

Creep under load at 100 °C (212 °F)

K factors on different sliding surfaces

K factors on different sliding surfaces

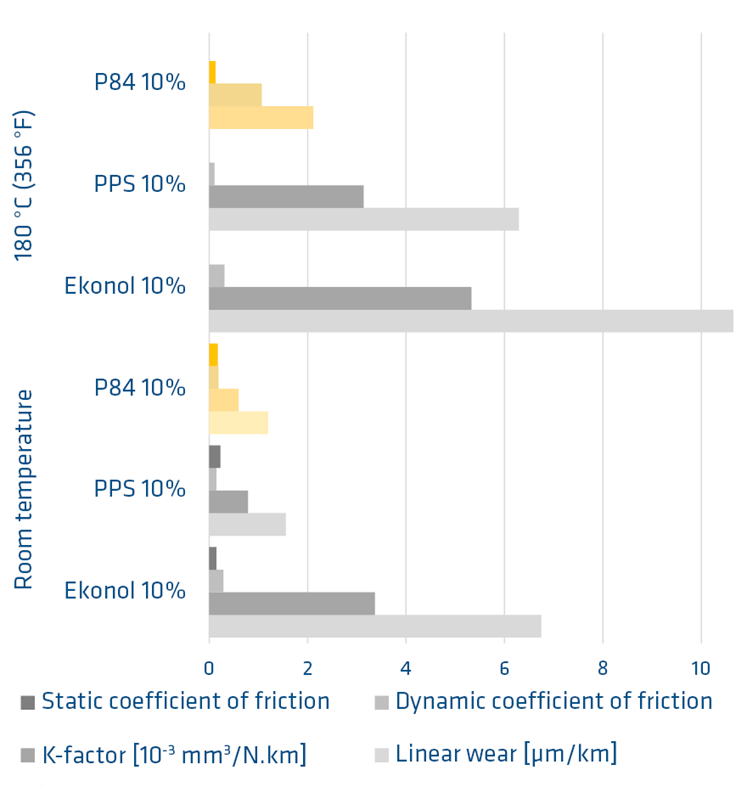

K factors on steel at different temperatures

K factors on steel at different temperatures

To offer extremely low porosity and smooth machined surfaces, TECAPOWDER PI is available in different grain sizes. For technical parts i.e. bearings, gliding elements and piston rings, 325 mesh is used. For skived films and dynamic seals 425 mesh and 1200 mesh is offered. The discolouration of the outside section will be reduced with finer particles.

The mechanical properties are strongly affected by the base PTFE resin. Fine PTFE particles offer a maximum on elongation and strength.

The sintering of high loaded compounds requires modified sintering temperatures over virgin PTFE. High temperatures up to 370 °C (700 °F) lead to a maximum in hardness and better tribological results. But this temperature must not be exceeded. More than 20 % TECAPOWDER PI powder needs to be sintered at lower temperatures (see table for conditions). Loadings of more than 30 % by wt. of P84 requires hot moulding conditions at a maximum temperature of 345 °C (650 °F).

For further information please contact [obfemailstart]dGVjYXBvd2RlckBlbnNpbmdlcnBsYXN0aWNzLmNvbQ==[obfemailend].