- Solutions & Services

- Engineering Solutions

- One-Stop Shop

- Processing Technologies

- Shapes Services

- Toll Compounding

- Webinars

- FAQs

- Sustainability

- Overview

- Environment

- Social

- Governance

- Compliance

- Products & Solutions

- Reporting

TECAPOWDER PI polyimides, the top end of high performance plastics, are useful in various demanding applications in industries such as aerospace, semiconductor, automotive, aircraft, plasma-welding and diamond wheel. No other plastic material keeps more superlatives in its designation than polyimides. TECAPOWDER PI is based on P84® by Evonik. BTDA and PMDA monomers reacted with isocyanate to produce fully imidised polyimide resins without the need for post curing.

Since 1984 the production and the development of TECAPOWDER has been situated in Austria, Lenzing. The Ensinger group is engaged in the development, manufacture and sale components made of engineering and high performance plastics. Further development of proven production techniques, new applications and international expansion have earned the enterprise a place among the leaders in its field.

TECAPOWDER PI are produced in different particle size distributions (mesh), fillers and qualities, depending on the intended end use and processing method.

TECAPOWDER PI STD (standard) grades are used for polymer alloys, plasma spray coatings, direct forming and composites. STD grades have no heat history and are fully reactive and sinterable.

TECAPOWDER PI SG yellow

TECAPOWDER PI SG HT yellow

TECAPOWDER PI solution grade materials are used in wire coatings and adhesives. SG grades are for solution blending in dissolving in DMF, DMSO or other polar solvents.

(vacuum predried and vacuum predried - high temperature)

TECAPOWDER PI VPD yellow

TECAPOWDER PI HT VPD yellow

TECAPOWDER PI HT VPD grades are highly crosslinked which allows their use as a filler in many fluoropolymers. Small mesh sizes enable good properties and uniform colour in sintered PTFE compounds.

TECAPOWDER PI HCM grades are used to mold high performance stock shapes (hot compression molding). Virgin grades use 40 mesh and our blended grade is 325 mesh. Heat history with HCM grades allow for compression molding without outgassing.

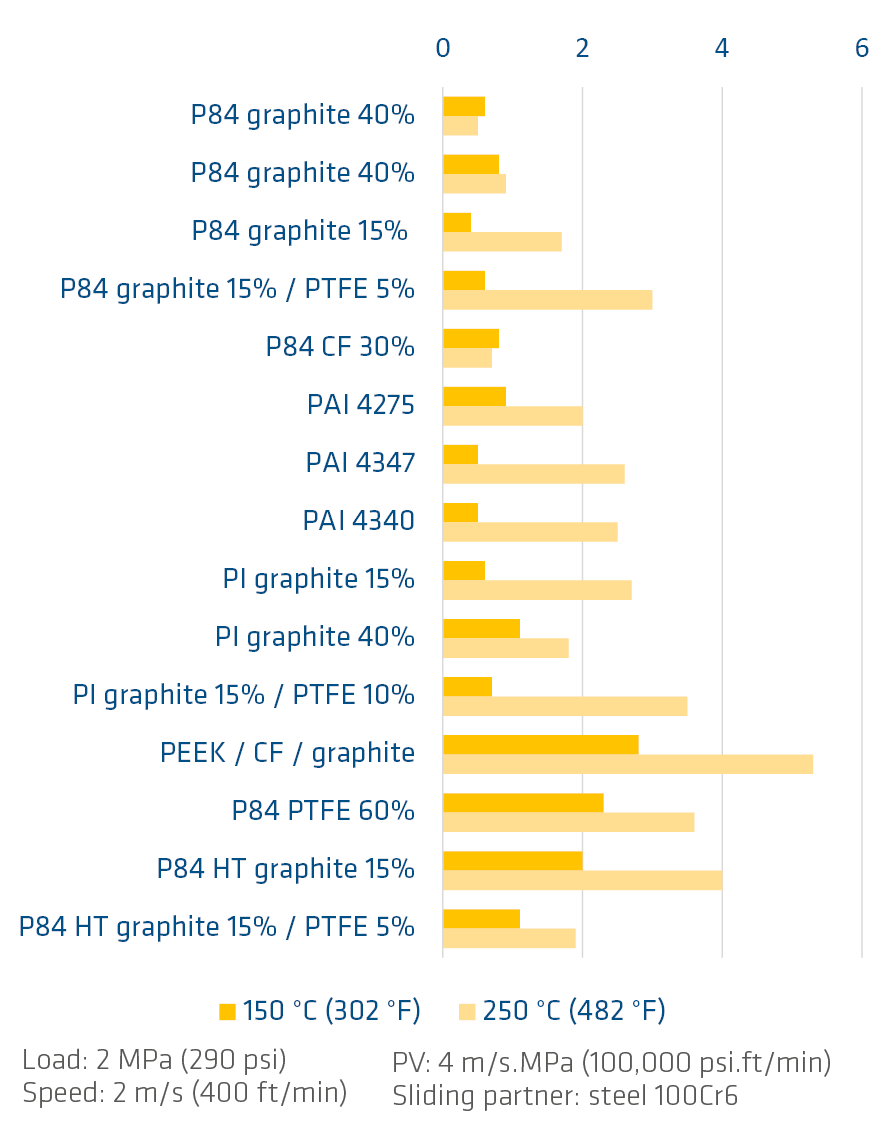

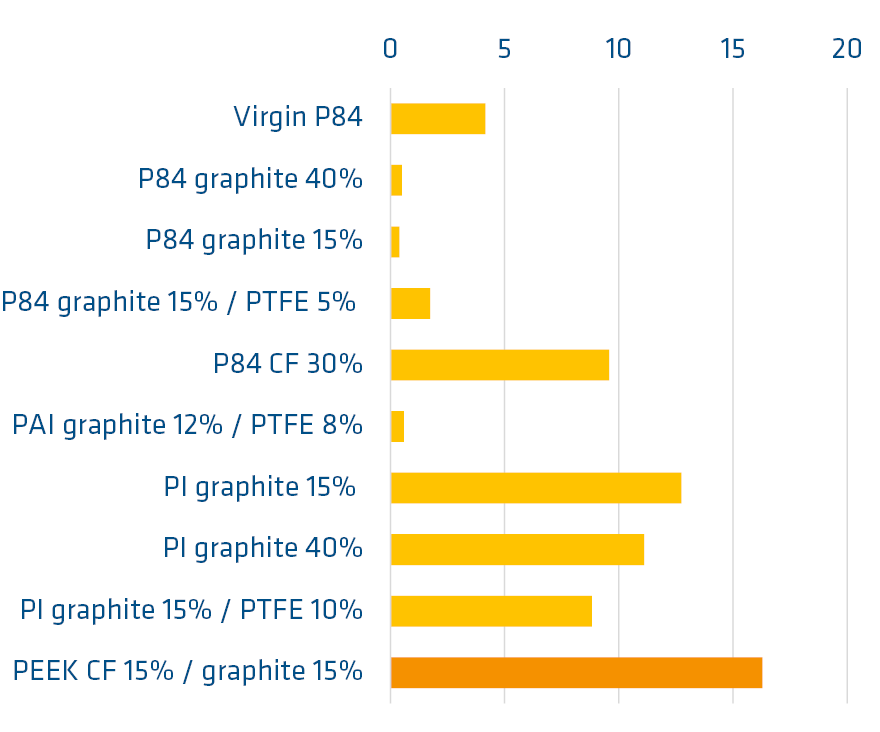

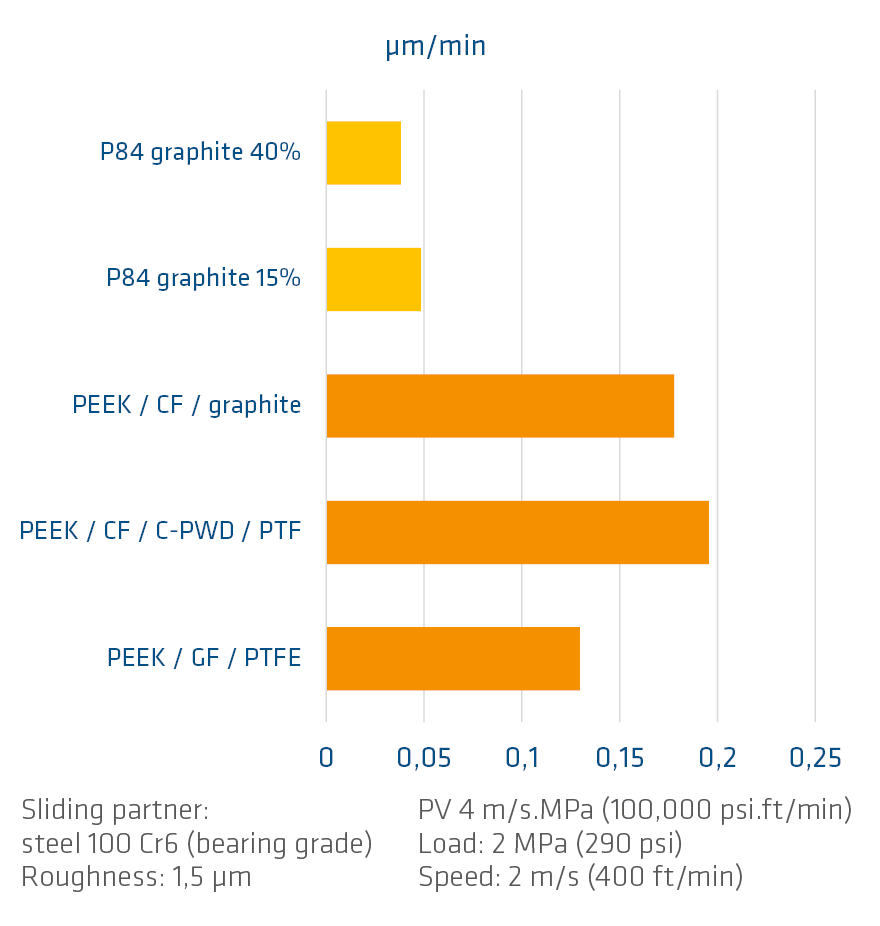

TECAPOWDER PI HCM blends contain various fillers for high-performance semi-finished products based on the end use requirements. Graphite grades are for excellent bearing and wear resistance parts.

(hot compression molding - high temperature)

TECAPOWDER PI HCM HT yellow

TECAPOWDER PI HCM HT blends

TECAPOWDER PI HCM HT yellow and blends are used for high performance stock shapes using our HT polymer. Heat history on the powder enables compression molding without outgassing and cracks in final stock shapes.

TECAPOWDER PI HCM grades are used to mold high performance stock shapes. TECAPOWDER PI STD can be used in composites.

TECAPOWDER PI solution grade materials are for dissolving in DMF, DMSO or other polar solvents for use in speciality coatings.

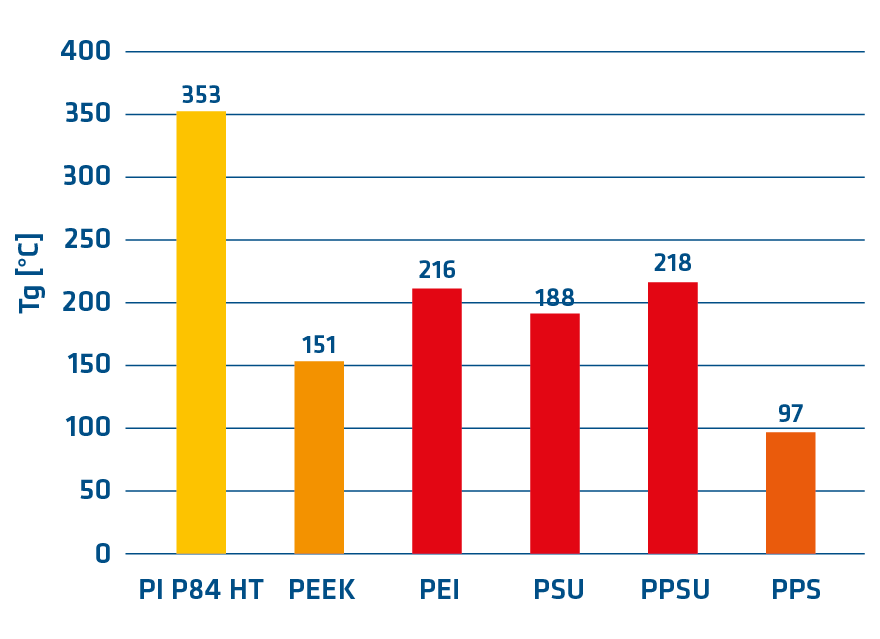

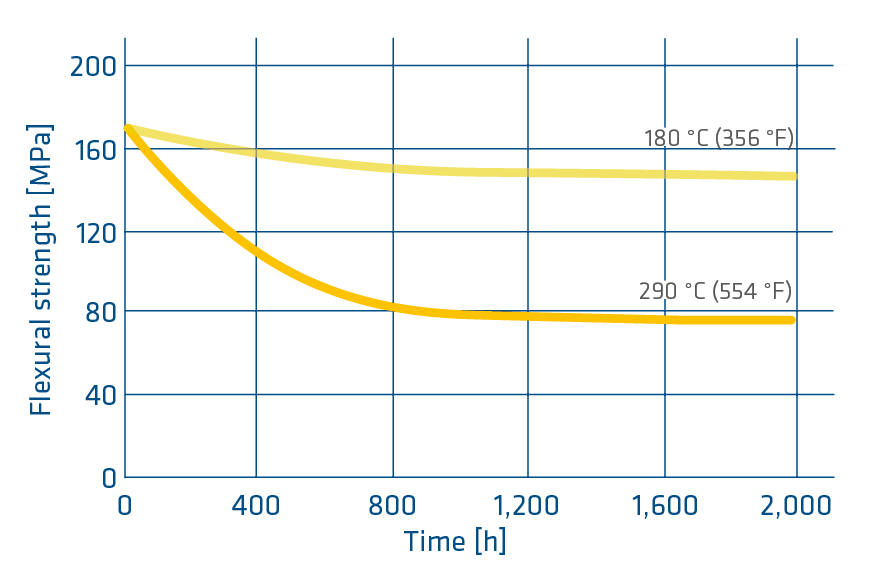

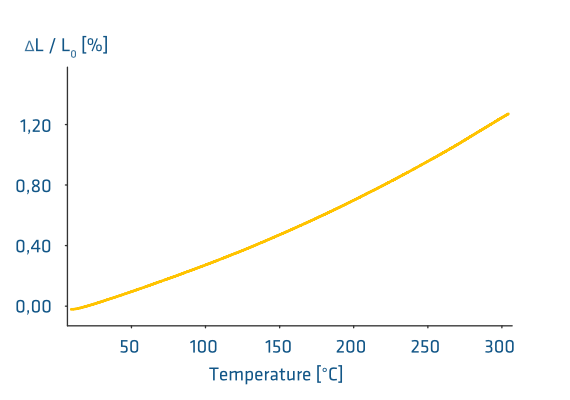

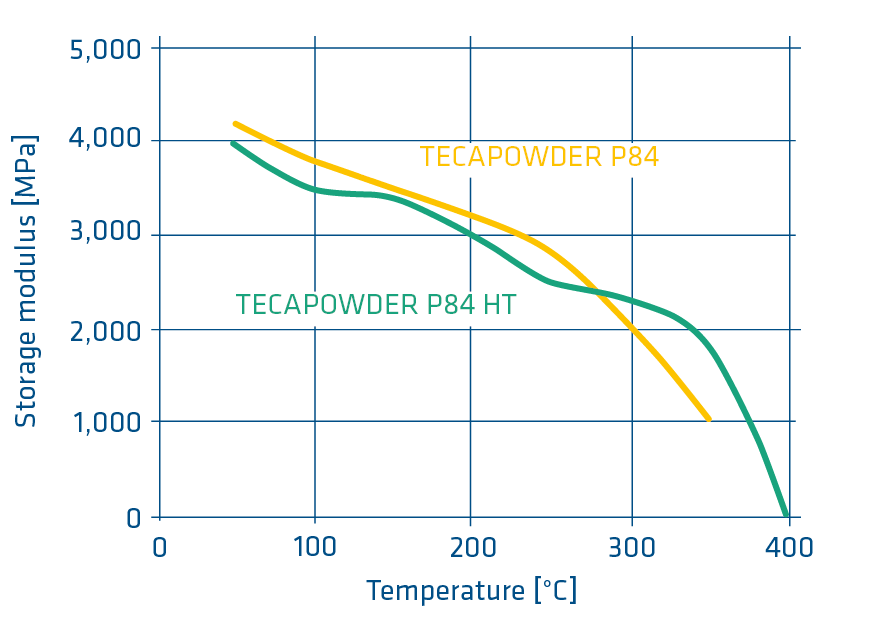

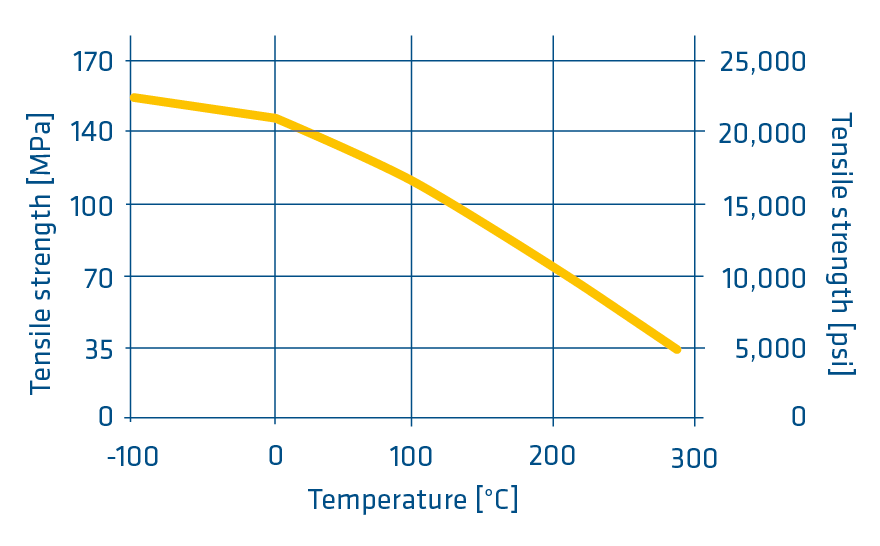

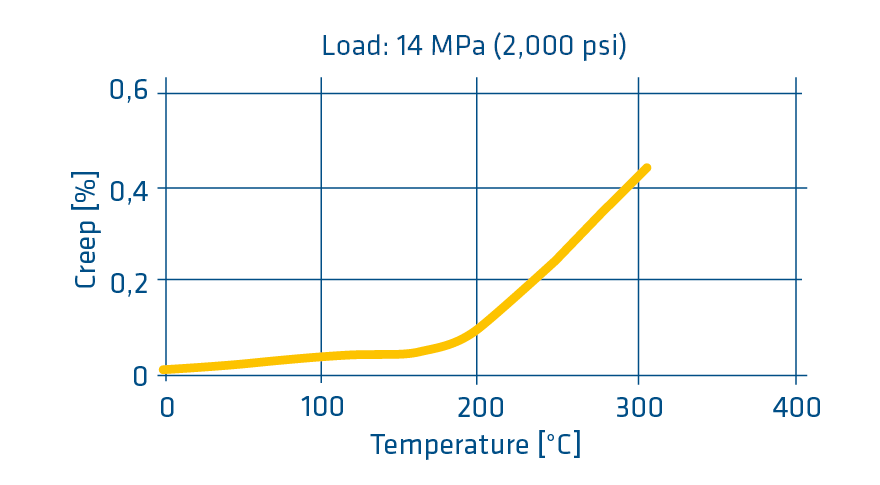

TECAPOWDER PI has an excellent long term thermal stability. It keeps its dimensional stability and flexural strength at elevated temperatures due to the high glass transition temperature. Creep under load at high temperatures is also excellent.

Base resin: TECAPOWDER PI HCM yellow, 40 mesh

Base resin: TECAPOWDER PI HCM yellow, 325 mesh, filler 15 % graphite

Base resin: TECAPOWDER PI HCM yellow, 325 mesh, filler 15 % graphite and 5 % PTFE

Base resin: TECAPOWDER PI HCM yellow, 325 mesh, blended with 30 % PTFE

Base resin: TECAPOWDER PI HCM yellow, 325 mesh, blended with 15 % MoS2