TECAPOWDER PI polyimide is a non-meltable polymer that improves the performance of grinding wheels in demanding applications. It is based on P84® by Evonik. The binding materials require high strength at elevated temperatures. These requirements are met by polyimides due to their chemical structure.

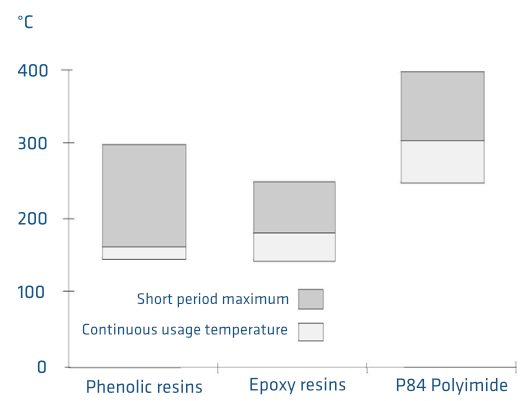

Polyimide bindings, in general, offer highest thermal stability in comparison with other polymers such as polyamides, epoxies and polyetherketones. This together with its extremely high strength make TECAPOWDER PI polyimide a natural choice for the binding resin in high quality diamond grinding wheels and which eliminate practically all other potential polymers except polyimides.

TECAPOWDER PI resin bonded wheels are capable of very high grinding speeds and, in many cases, outlast standard epoxy or phenolic wheels by a factor of 2.

The physical properties of TECAPOWDER PI meet the requirements, which are demanded from grinding wheels. TECAPOWDER PI has a high glass transition temperature of 330 - 340 °C (626 - 644 °F) based on the moulding parameters used to sinter the resin.

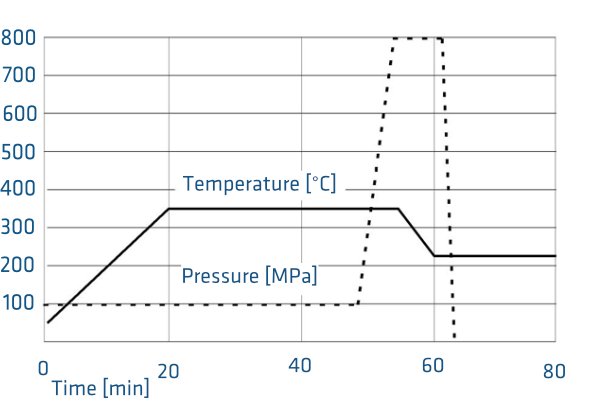

The hardness, brittleness and abrasion capacity of TECAPOWDER PI wheels can be influenced by processing. Varying the sintering temperature and dwell time can lead to different mechanical properties of the resin. As the process temperature and dwell times rise, the grinding area becomes harder and more brittle. This temperature moulding window is between 330 and 360 °C (626 and 680 °F).

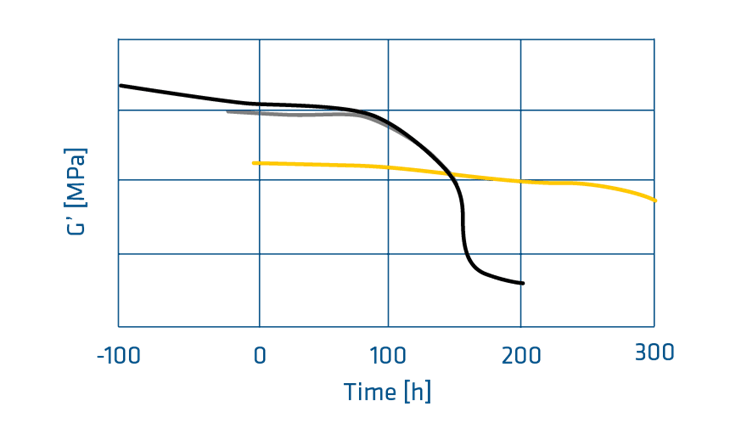

TECAPOWDER PI polyimide resin maintains a high level of stiffness at elevated temperatures.

TECAPOWDER PI resin is available in powder grain sizes of 200 mesh, 325 mesh, 425 mesh and 1200 mesh. Usually powder grain size of 325 mesh HCM is used. Primer solutions of 10 % P84 in NMP (n-methyl-pyrrolidone) is also available.

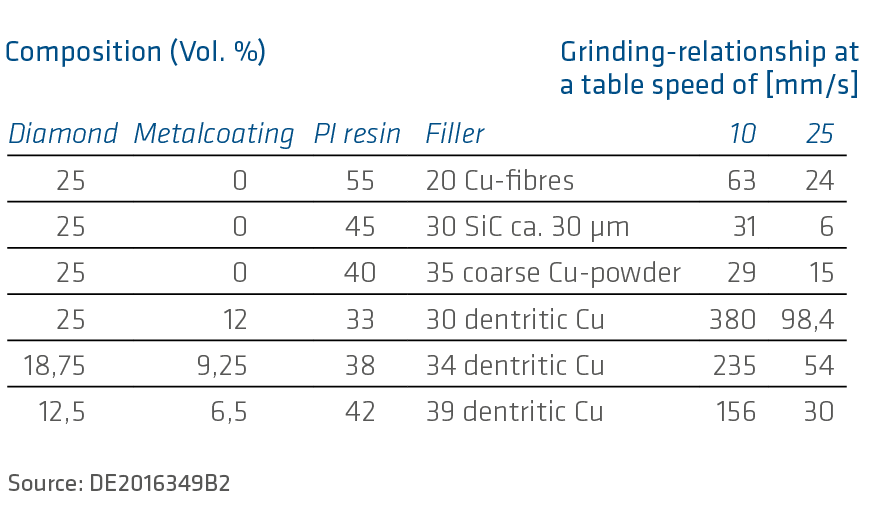

To obtain successful grinding results, it is necessary to utilise the appropriate resin and optimise the formulation depending on the end-use. Listed here are various formulations tested in dry grinding applications.

The use of Ni coated diamonds is necessary. In dry grinding applications, approximately 30 % copper powder should be added.

We recommend silicone oil spray to applied in a very thin coating on the mould surfaces.

Wacker Chemical Corporation

3301 Sutton Road

Adrian, MI 49221

USA

Phone +1 517 264 8500

Evonik Industries

Goldschmittstr. 100

45127 Essen

Germany

Phone +49 201 173 01

Fax +49 201 173 3000

Test mechanical properties:

When first learning to process TECAPOWDER PI, it is recommended to mould the neat resin into shaped articles to test mechanical properties. This should lead to an optimised processing of PI resin.

Methods of manufacturing grinding wheels:

In manufacturing grinding wheels, two different methods are commonly used:

In both cases the sintered wheel can be released at 230 °C (446 °F). Post curing is not necessary! Especially in the production of 1Al wheels, a resin bounded hub is often used. We split it up into:

In case of phenolic prepreg hubs the grinding area is moulded first. The prepregs are added afterwards into the outside ring and moulded as recommended for this resin. Due to the high thermal stability of P84 no damage of the grinding area will be obtained.

Under the use of metal/resin blends we recommend the use of a 70 % metal and 30 % resin composition. The metal component can be a blend of bronze and aluminum. This hub has to be sintered as an independent part of the wheel, afterwards the grinding area is added by sintering it on to the disc.

For further information, please contact: [obfemailstart]dGVjYXBvd2RlckBlbnNpbmdlcnBsYXN0aWNzLmNvbQ==[obfemailend]