- Solutions & Services

- Engineering Solutions

- One-Stop Shop

- Processing Technologies

- Shapes Services

- Toll Compounding

- Webinars

- FAQs

- Sustainability

- Overview

- Environment

- Social

- Governance

- Compliance

- Products & Solutions

- Reporting

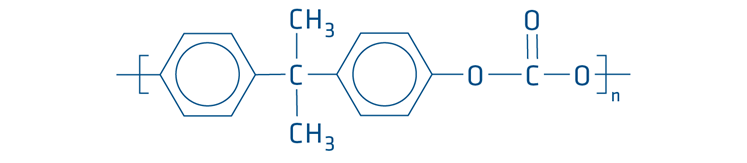

Polycarbonate is referred to by the abbreviation PC and is an amorphous thermoplastic that has high transparency due to its low crystallinity. This clear polycarbonate plastic offers good electrical insulation properties and excellent toughness. PC plastic can be used in a wide temperature range. At up to 120 °C, the plastic retains its rigidity and has very high impact strength even at low temperatures.

Polycarbonate plastic is also characterised by its UV and weather resistance, but is only moderately resistant to chemicals. The material only exhibits optical clarity when it is mechanically or chemically polished.

Polycarbonate manufacturers generally offer their polycarbonate material in the mid-price segment, which makes the material optimal from a value standpoint.

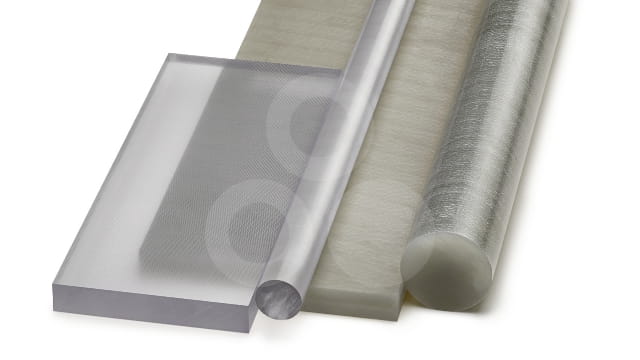

Polycarbonate plastics are manufactured by Ensinger under the brand name TECANAT and are produced as stock shapes in the following forms

In addition to the natural and black versions, our TECANAT family also includes a version with glass fibre filling:

Glass filled polycarbonate offers higher strength, better impact resistance and superior dimensional stability. The modified polycarbonate can still be machined similarly to its unfilled counterpart. Glass filled PC is not translucent, but can be used in more demanding applications thanks to its improved properties.

Polycarbonate properties: