Plastics represent an optimal solution for use in the aerospace industry due to their weight compared to metals.

To be considered for application in aircraft interiors, materials must meet various technical requirements. The requirements serve to limit the consequences of a fire in the cabin, thus maintaining passenger safety as much as possible.

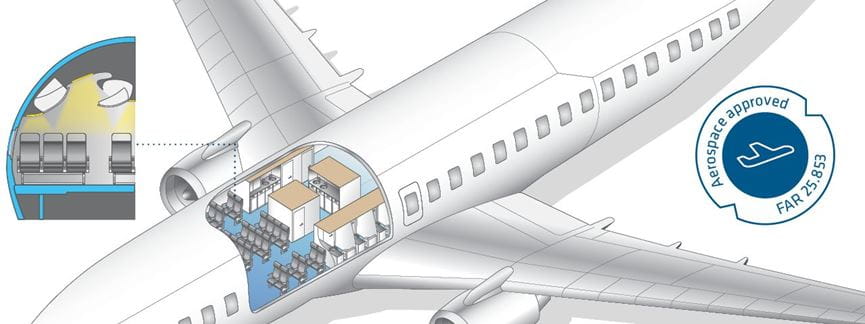

To ensure fire protection in an aircraft, the U.S. Federal Aviation Administration (FAA) prescribes various fire tests (e.g. FAR 25.853). These tests demonstrate that materials used in aircraft meet specific performance criteria when exposed to heat or flame.

When looking at the industry's established thermoplastics, high performance materials such as PEEK, PEI, and PPS meet the flammability requirements (usually without modification). This is usually not the case with standard materials such as PA, unless they are modified with special additives.

For this reason, we have developed various plastics with a flame retardant additive. These materials meet the typical requirements of aircraft interiors and can be a cost-effective alternative to high performance materials if high temperature resistance or high mechanical strength is not required.

Aircraft interior materials in accordance with FAR 25.853:

Materials for use in aircraft interiors must meet certain flammability requirements. However, it is the components' actual location in the aircraft that will determine whether only flammability is tested or if the full FST ("Fire", "Smoke" and "Toxicity") test is required to be performed (see below):

Ensinger's flammability test for plastics indicates the verified thickness, which is the thinnest wall thickness allowed on the finished part made of our plastics. To find out which test a particular material has passed, please refer to the material data sheets. Certificates of flammability testing will be provided at the time of order upon request.

The test results provided for our plastics can be used by our customers to determine an indication of the potential results of final FST tests on machined parts or their subassemblies. The results help our customers quickly and reliably select the right material for a particular application.

If you have any further questions, please feel free to contact us. If required, we can also carry out further tests. For example, we can test for additional levels of flammability upon request.

The requirements for the application of materials in aircraft and in particular in aircraft interiors are very similar worldwide and are clearly described by different regulatory authorities. Regulations for aircraft are primarily determined by two equivalent standards and are listed as follows by the associated agencies:

Large commercial aircraft are covered by section "25" for both standards, and aircraft interiors are covered by section "853". Therefore, we refer to "FAR 25.853", "JAR 25.853", "JAR-25, § 25.853", "FAR Part 25, § 25.853", "14 CFR Part 25", "CS 25.853".

For the definition of more detailed instructions and safety precautions, individual aircraft manufacturers have created their own internal documents, which are comparable in content with regard to the FST requirements.

The various tests are described in Appendix F of FAR/CS 25. All materials must pass the vertical fire test. Some components for aircraft interiors, for example the ceiling, wall panels, partitions, fixtures for galleys, large cabinets, or baggage compartments in cabins, must simultaneously pass all smoke emission and toxicity tests and a heat release test.

The following table identifies the interrelationships between the test methods in accordance with FAR 25.853, AITM and BSS.

Test description |

FAR 25.853 |

Airbus ABD 0031

|

Boeing

|

| Flammability 60 seconds Vertical |

FAR Part 25, § 25.853 (a) and Appendix F, Part I, |

AITM 2.0002A | BSS 7230 F1 |

| Flammability 12 seconds Vertical |

FAR Part 25, § 25.853 (a) and Appendix F, Part I, |

AITM 2.0002B | BSS 7230 F2 |

| Flammability 15 seconds Horizontal |

FAR Part 25, § 25.853 (a) and Appendix F, Part I, |

AITM 2.0003 | BSS 7230 F3 |

|

FAR Part 25, § 25.853 (a) and Appendix F, Part I |

BSS 7230 F4 | ||

| Smoke Density |

FAR Part 25, § 25.853 (d) and Appendix F, Part V |

AITM 2.0007A & B | BSS 7238 |

| Combustion Toxicity | N/A | AITM 3.0005 | BSS 7239 |