Your partner for high-performance plastics

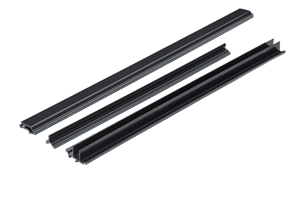

Customised production from one-offs to full series

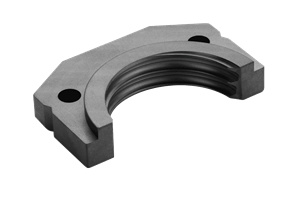

Precision Finished Parts

Uncompromising quality

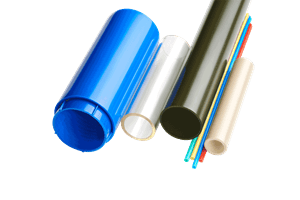

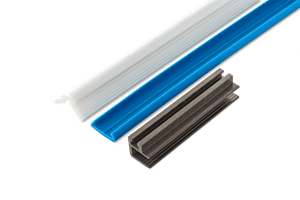

High-Performance Products

Demanding materials ....

Material Portfolio

... for exceptional requirements

Engineering Solutions

Solutions for everyone

Industries

Introducing

Ensinger