Your partner for high-performance plastics

Customised production from one-offs to full series

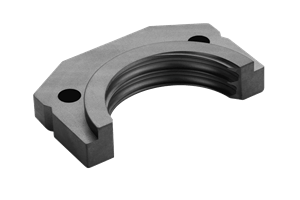

Precision Finished Parts

Uncompromising quality

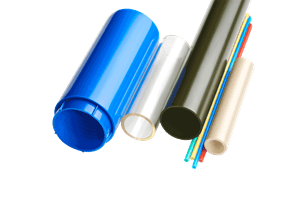

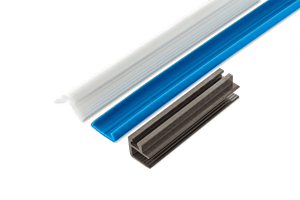

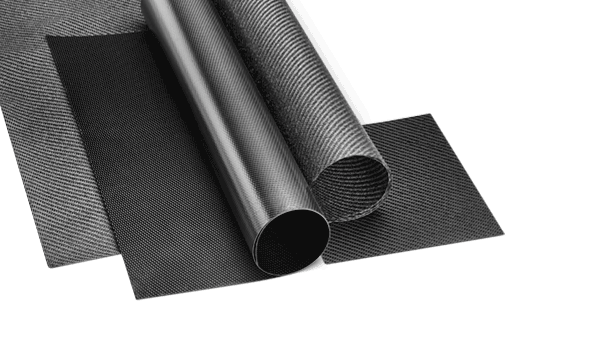

High-Performance Products

Demanding materials ....

Material Portfolio

... for exceptional requirements

Engineering Solutions

Solutions for everyone

Industries

Introducing

Ensinger

Work with us

Career at Ensinger