Near-Net-Shape manufacturing of plastic parts

Efficiently to the final shape

At Ensinger, the manufacture of Near-Net-Shapes, also know as "close-to-contour manufacturing", is a key approach for producing complex components made of high-performance plastics in a resource-efficient and economical way. During production, the blank is given a shape that is almost identical to the final contour, meaning, the result being that only a few minor machining steps are required to meet the final specifications.

Ensinger manages the entire process chain — from developing and manufacturing the material, to producing the Near-Net-Shape blanks, and then on to final machining.

This approach endeavors to reduce material usage and processing costs, shorten production times, and increase overall manufacturing efficiency in a sustainable way. Near-Net-Shape technology is particularly advantageous for combining complex geometries with high-performance plastics, such as PEEK and thermoplastic fibre composites, which are used in the medical technology, aerospace and the semiconductor industries.

Benefits of near-net-shape molding

-

Material efficiency – Less waste, more added valueConventional machining often results in substantial material loss, because components are machined entirely from solid plastic semi-finished products. In contrast, Ensinger Near-Net-Shape manufacturing relies on preforms that are close to the final contour. This means only minimal finishing is needed, which greatly reduces waste and delivers significant material savings.

-

Time and cost savings – Less processing, faster processesClose-to-contour prefabrication reduces downstream machine running times, since the machining effort for complex components is significantly reduced. In large serial production in particular, this significantly shortens production times and makes processes more efficient.

-

Challenging geometries – new scope for design and functionThanks to Near-Net-Shape processes, Ensinger is opening up new possibilities in component design. Parts with high precision and complex geometries – which were previously difficult or impossible to produce using methods like injection moulding – can now be manufactured economically. This includes components with undercuts and functionally integrated structures.

The result is maximum design freedom, integrated functions, and high-performance plastic components precisely tailored to your application. -

From raw materials to solutions – One-Stop Shop EnsingerAt Ensinger, we bring together comprehensive expertise in plastics processing and a wide range of technologies. Whether it's injection molding, direct forming, machining, or other plastics processing methods, Ensinger carries out all processing steps in-house. This means: single point of contact, consistent process control and a finished end product from a single source — efficient, reliable and precisely tailored to your application.

Near-net-shape processes

Near-Net-Shape in injection molding

Near-Net-Shape in Compression Moulding

This process is ideal for producing highly stressed, complex, or three-dimensionally curved components that would otherwise require time-consuming milling from fiber-reinforced plates. Near-Net-Shape manufacturing significantly reduces material usage. Unlike milling from a composite plate, Near-Set-Shape compression molding allows the fibers to be laid in the mold along the defined direction of force. This allows the mechanical reinforcement to be precisely tailored to the expected load patterns during use. These customised composite components are used in medical technology, mechanical engineering, sports, and aerospace.

Near-Net-Shape in Direct Forming

The powdered material is pressed into blanks that closely match the final shape, which are then sintered. This process can be used to produce parts that have to withstand high mechanical or thermal loads.

Subsequent processing, such as finishing or precise milling, can be carried out at Ensinger or your location. This allows for the realisation of material- and time-efficient solutions that are precisely tailored to demanding applications.

Near-net-shape applications

PEEK housing

for CT application

Material:

Made from PEEK natural

Blank production by injection molding, machining of joint and inner surfaces, surface finishing, assembly of components

Retractor

for fixing systems

Material:

Made from thermoplastic composite TECATEC PEEK CF50 MT black

Contour-accurate production using compression molding, recesses created directly during the pressing process or by subsequent machining

Bottle gripper

for handling systems

Material:

Made from Polyimide TECASINT 6032

Production of the blank by direct molding, milling of specific functional dimensions, thread insertion

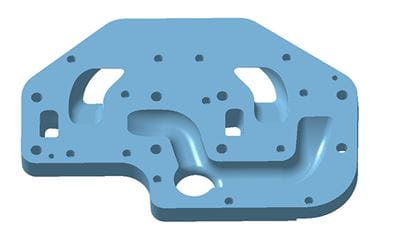

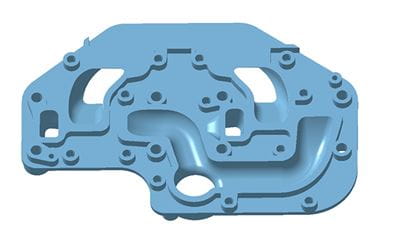

Gear box

for e-bikes

Material:

Made from PEEK material TECAPEEK TRM CF 30

Production of the blank by injection molding, milling of the gear teeth