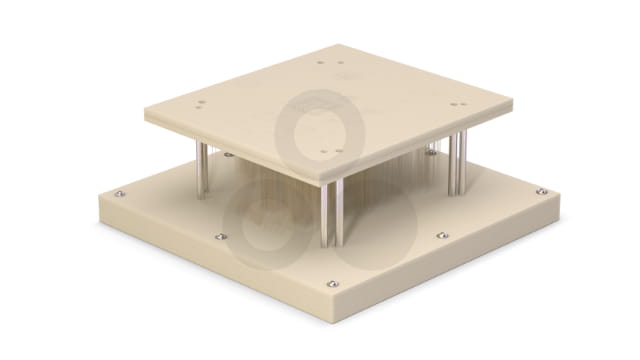

Fiber reinforced plastics and injection molded plates tend to contain residual stresses that cause warpage and deformations while machining, thus making it difficult to realize small geometries with tight tolerances. The filler system and extrusion molding method of TECAPEEK CMF allows residual stresses to be significantly lower than fiber reinforced plastics or injection molded materials. For parts requiring higher temperature resistance, Ensinger's polyimide TECASINT are produced with compression molding, also offering very low level of residual stresses. Consequently, better dimensional stability and reduced deformation while machining enable smaller pitches and higher hole position accuracy. For parts besides the contact plate, such as body parts, where micro hole machining is not required, Ensinger’s glass fiber reinforced materials can be a cost-efficient option.

Material with high residual stress versus material with low residual stress level

Example of machining down a 6 mm sheet to 2 mm thickness

The material properties also have an influence on the dimensional stability, as water absorption and thermal expansion can cause part deformations. Ensinger's TECATRON PPS, TECAPEEK, and TECAPEI plastics for test sockets offer low levels of water absorption, while materials with higher water absorption like PAI and PAI GF30 can cause issues in tight tolerance alignment. For higher temperature applications, the special polyimide type TECASINT 4011 and in particular TECASINT 4111 offer lower water absorption than industry standard polyimide, opening up new design possibilities for high temperature test sockets.

Plastics with glass fiber reinforcement

Plastics without glass fiber reinforcement

Plastics with glass fiber reinforcement

Plastics without glass fiber reinforcement