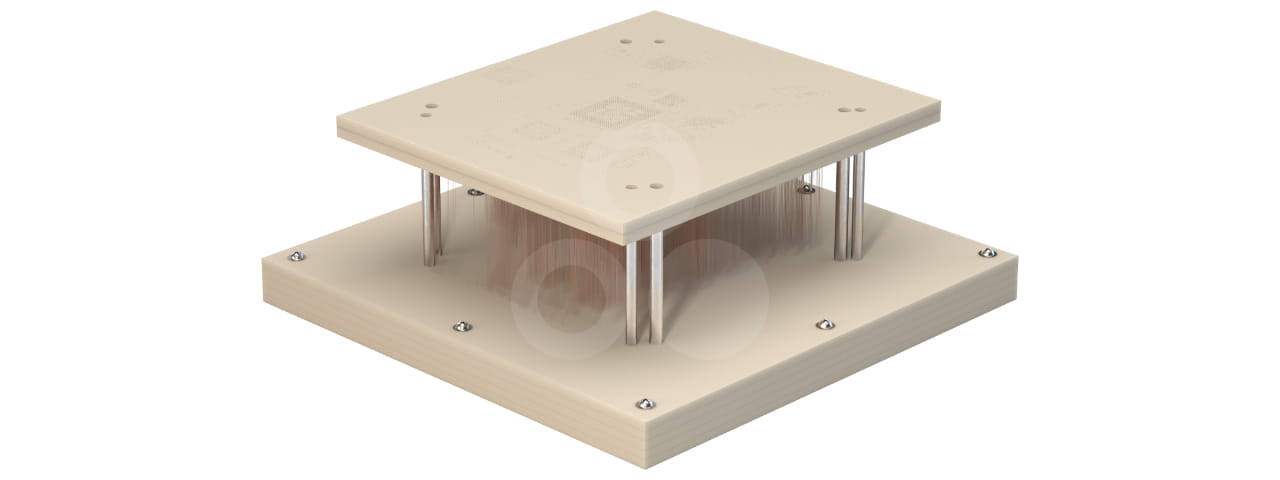

PCB Inspection Fixtures

Printed Circuit Boards (PCBs) serve as the platform for linking electrical components and connectors and are used in almost all electronic devices. During the fabrication and assembly process, PCBs must undergo thorough inspections to ensure that the product functions correctly. As PCBs have gotten more complex and advanced, so have the inspection techniques used to check for shorts, opens, or malfunctioning solder joints, and to ensure that performance values are within the required tolerance levels.

PPS plastic - a good choice but with challenges

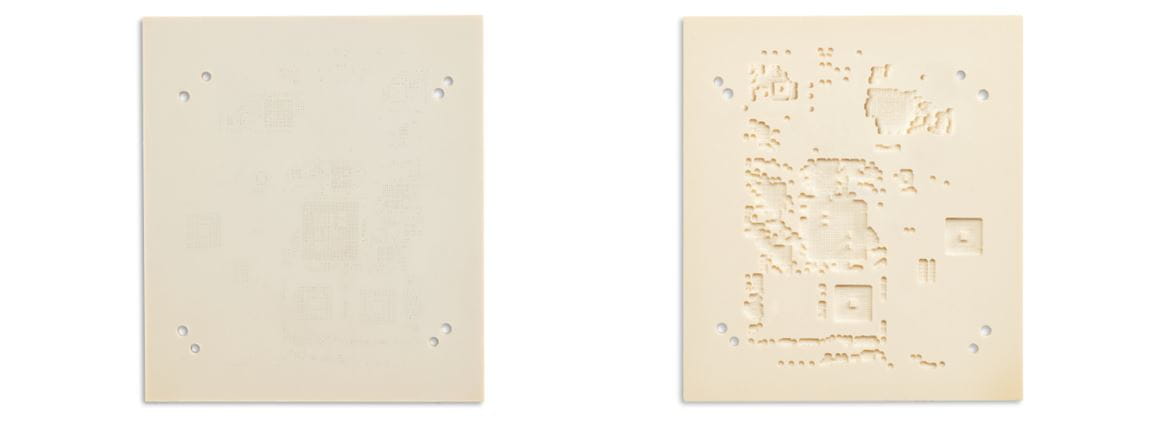

From a range of different semiconductor plastics, PPS is often chosen for this application due to the high requirements. This is because drilling micro-holes for inserting the wire probes requires a material with a balanced ratio of stiffness and ductility to ensure minimal burr formation and cracking.

The material also needs to be dimensionally stable with minimum water absorption and thermal expansion levels to ensure the array of holes remains within tolerance. Besides the influence of the material itself, dimensional stability is also influenced by the molding technique, as residual stress can result in warpage while machining. Moreover, a material with higher wear resistance is preferred, as the wire probes abrade the inner wall of the contact plate while the fixture is pressed against the PCB.

However, not every PPS material is equally suitable, as the extrusion of PPS is characterised by a number of challenges. For this reason, in cooperation with leading manufacturers of components for PCB inspection equipment, we have developed Ensinger's TECATRON SX natural, a material made of polyphenylene sulfide (PPS), which has characteristics that make it particularly suitable for contact plates and and fixture body parts.

Making the perfect match in semiconductor plastics