Ensinger GmbH now provides full and product-specific carbon footprint data for its range of plastic stock shapes. By doing so, the company sets a new standard of transparency in material selection and supports customers in making informed, sustainable choices. Each value is stated as a "Product Carbon Footprint" (PCF) per kilogram of material, calculated on a cradle-to-gate basis and in accordance with international standards.

“Our customers want to understand the climate impact of their material choices – and we give them the tools to do just that,” says Nina Finkbeiner, Head of Central Market Functions at Ensinger. “With PCF values, we make the environmental impact of our products measurable, transparent, and comparable – across our entire stock shape portfolio.”

The PCF calculation follows the DIN EN ISO 14040ff standard and the IPCC GWP 100a method, incorporating reliable primary and background data. Ensinger applies a sector-wide methodology developed by EPSM (Engineering Polymer Shapes for Machining Association), ensuring that the results are comparable across manufacturers.

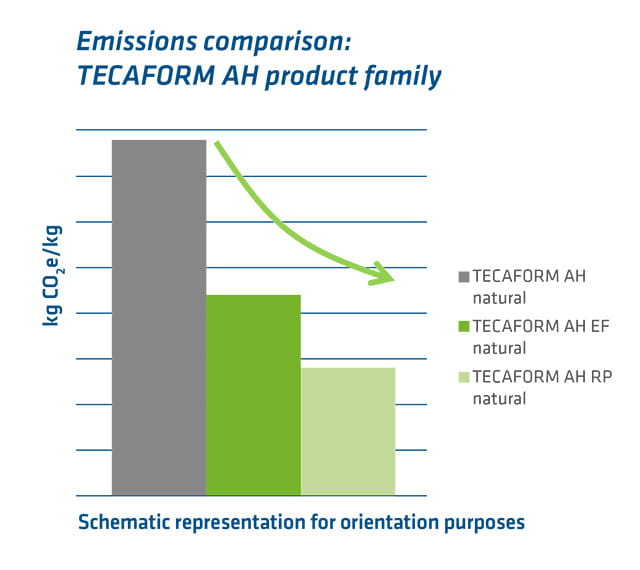

A closer look at the CO₂ values within the TECAFORM product family highlights the potential of more sustainable materials. The biobased EF variant already shows a significantly lower footprint compared to the fossil-based version, while the RP type – based on recycled secondary raw materials – offers the lowest CO₂ footprint in the series.

Emission comparison: TECAFORM product family

Emission comparison: TECAFORM product family

Ensinger sets a new standard of transparency in material selection and supports customers in making informed, sustainable choices

Ensinger sets a new standard of transparency in material selection and supports customers in making informed, sustainable choices

TECAFORM AH RP: The plates, rods, and tubes are extruded from recycled secondary raw materials

TECAFORM AH RP: The plates, rods, and tubes are extruded from recycled secondary raw materials

Ensinger GmbH

Phone +49 7032 819 202

[obfemailstart]am9lcmcuZnJhbmtlQGVuc2luZ2VycGxhc3RpY3MuY29t[obfemailend]