Ensinger Microsystems Technologys (EMST) based sensor manufacturing solutions enable functionalisation, integration and individualisation of sensors through PEEK-based wafers and our newly developed technology, offering solutions beyond traditional options. With this, we are introducing a paradigm shift in sensor manufacturing. Our sensors based on high-performance plastic wafers provide an innovative, functionalisable, customisable and fully integratable alternative, replacing components with a new generation of sensors.

With local manufacturing, established supply chains and microsystems experts at every stage, we ensure the highest quality from the raw material to the finished sensor. Restrictions such as complex process chains, customisation options depending on the lot size or cleanroom constraints hinder creativity and innovation in sensor technology. Our solution frees sensors from unnecessary constraints, enabling a fresh perspective on manufacturing and fostering the development of new, innovative, cost-effective, customisable and sustainable solutions across industries worldwide.

With in-house production and partnerships with the "Institut für Mikroproduktionstechnik der Leibniz Universität Hannover" (IMPT) and "Hahn Schickard Gesellschaft für angewandte Forschung e.V.", we provide limitless technical possibilities. By combining the advantageous properties of the high-performance plastic TECACOMP PEEK LDS with microsystems technology processes, functionalised, integrated and fully customisable sensors are created.

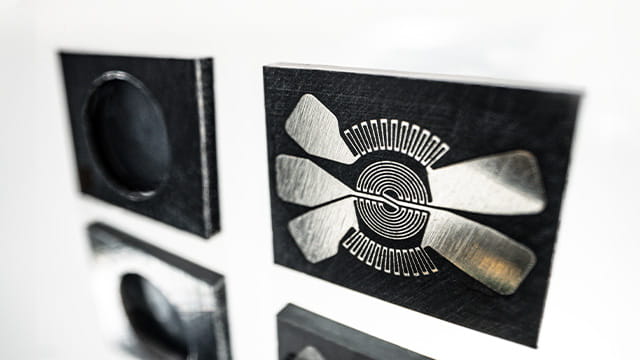

Explore our diverse sensor solutions, including pressure, strain gauge, temperature, flow, and magnetic field sensors (AMR, GMR and eddy current).

Our high-performance plastic-based wafers address challenges such as heat, outgasing and chemical resistance, making them suitable for replacing silicon, glass or ceramic-based wafers. But our EMST takes sensor manufacturing one step further: by implementing thin-film structures that incorporate different metals or alloys for tailored functionality, we create functionalised sensors that can be fully integrated due to the ease of processing the material. Offering novel contact options on both sides, our easy-to-process materials ensure customised solutions. This allows us to create individual solutions for size, quantity, sensor placement, sensor number and more. With Ensinger Microsystems Technologies new approach, we manufacture existing components more easily and efficiently, or create completely new, integrated solutions.

Benefit from:

Our current areas of application for EMST sensors include:

We are also happy to advise you on the possibilities of sensors with EMST.