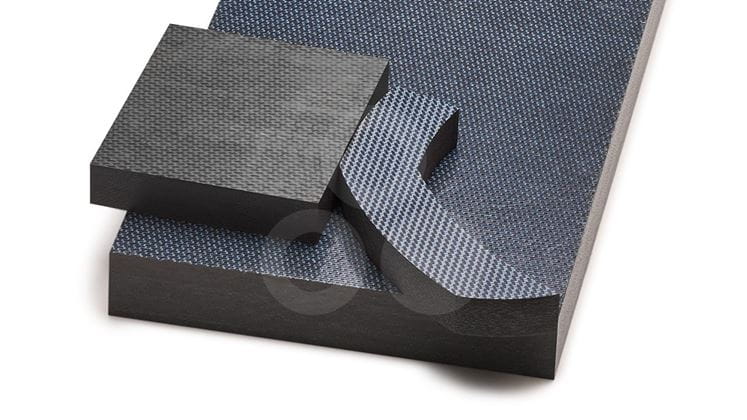

For applications where the mechanical properties of unreinforced or short-fibre-reinforced semi-finished plastic products such as extruded sheets or rods are not sufficient, continuous-fibre-reinforced composites can be an excellent alternative. Thanks to continuous fibre reinforcement (usually woven glass or carbon fibre fabrics), these plates offer high mechanical properties otherwise only achieved by metals, while being significantly lighter than them.

Thanks to the use of thermoplastic matrix materials, the sheets have the same advantages as unreinforced thermoplastic sheets, such as high impact strength, consistent mechanical properties over a wide temperature range, chemical resistance and high elongation at break. In addition, these plates are characterised by their low thermal expansion and very high mechanical properties. The matrix material can be selected according to the application and covers a wide range of customer requirements.

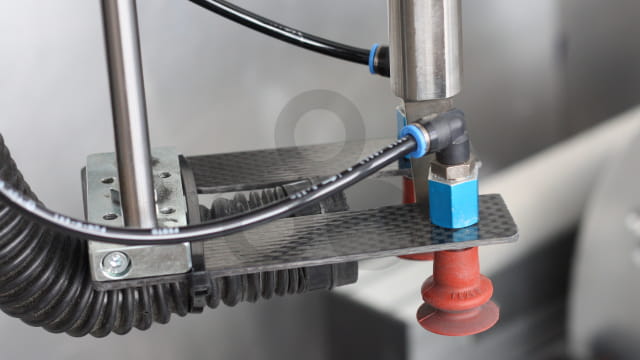

Sheets of continuous fibre-reinforced thermoplastics can be processed into finished parts of excellent quality with minimum tolerances by waterjet cutting as well as by conventional machining methods. It is important to note that suitable equipment and processing parameters are required.

By using thermoplastic composite materials, sheets up to 95 mm thick can be produced. In addition to the standard materials, customised material combinations or fibre orientations are also possible on request.

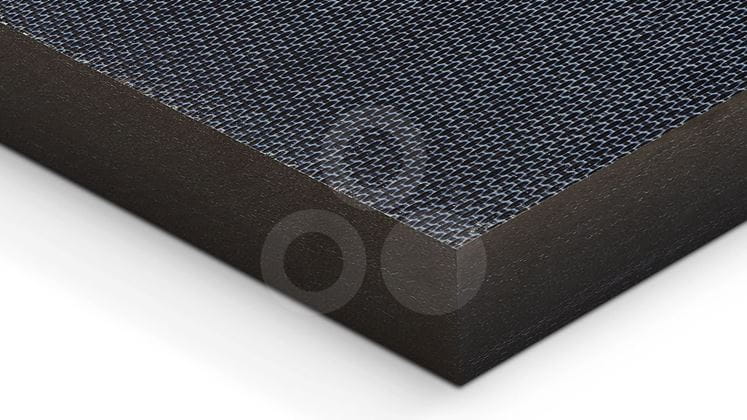

Our thermoplastic composite sheets can be supplied in thicknesses from 1 mm to 55 mm in sizes up to 1200 x 900 mm and in thicknesses up to 95 mm in sizes up to 500 x 600 mm.

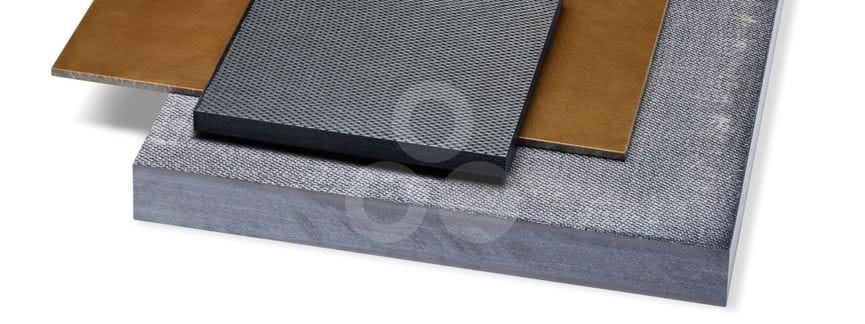

Standard products are glass or carbon fibre reinforced PEI and PPS, glass fibre reinforced PA66 and carbon fibre reinforced PC and PEEK. Other matrix and fibre combinations, fibre architectures or customised fibre constructions can be offered on request.

Our proven TECATEC PEEK MT CW50 black sheets are available for applications in medical technology.

The composite panels have densities between 1,3 and 1,8 g/cm³ and thus, holds a similar specific weight as unreinforced or short-fibre reinforced panels. However, due to the continuous reinforcing fibres, the mechanical properties are drastically increased and reach a metal-like level. Compared to unreinforced polymer sheets, continuous fibre reinforced sheets achieve 5 times higher values for tensile strength and modulus of elasticity.

Continuous fibre reinforced thermoplastics have extremely low coefficients of thermal expansion (CTE) in the range of about 3 to 10x10-6 K-1. This property is of great importance for applications where parts are exposed to temperature variations over a wide range and high precision is required.

The thermoplastic matrix gives the plates high impact strength, which is significantly higher than sheets with thermoset matrix such as epoxy or phenolic resins. In addition, the high elongation at break of the thermoplastics provides a tough, non-brittle fracture behaviour. For some applications, the inherent vibration damping of the matrix can also be a relevant advantage.

Achieve your goals with thermoplastic composites without long and costly development times. No minimum order quantity is required for our TECATEC PA66, PC, PEI ,PPS and PEEK sheets.