The food industry has changed significantly in recent decades, and many areas have evolved from smaller hand crafted operations to much larger industrial production. Along with this, the standards and regulations for avoiding allergens, food contaminants and pathogens have also become much more strict.

Ensinger's food-compliant stock shapes meet these requirements, and our highly qualified team knows what is important when it comes to manufacturing components for the food sector. By means of CNC turning and CNC milling, a wide variety of components can be manufactured in compliance with the tightest tolerances. Thanks to our wide range of options for finishing machined parts, we can offer our customers a consistent manufacturing process of the highest quality.

For more information on the services offered by Ensinger Machined Parts, click here

Thanks to the large product and manufacturing portfolio in the plastics sector, in addition to the classic semi-finished products, product-specific extruded profiles and tubes are also available as blanks, which we can machine into your specific finished part.

Depending on the material, specific certificates such as FDA approval for raw materials, compliance with Regulation 1935/2004/EU, 10/2011/EU as well as 2023/2006/EU on Good Manufacturing Practice (GMP) for food contact materials and articles can be issued. For the Chinese food market we offer certificates according to the Chinese GB standards.

Our staff will be happy to advise you on this in order to find the perfect combination for your application.

Food-grade machined plastic products from Ensinger are used in various applications and plants. Typical areas of application are the baking industry, meat and fish industry or even the beverage industry.

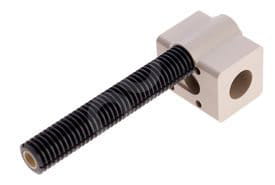

High-precision components can be produced efficiently by CNC machining.

Machined from extruded TECAPEEK black

Machined from TECAPEEK natural and TECAPEEK PVX black