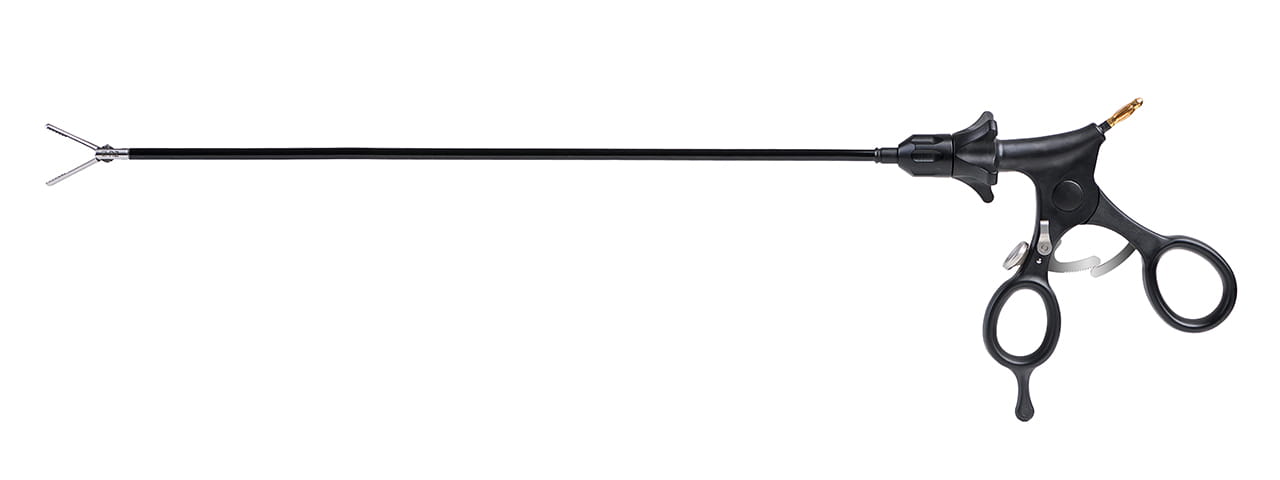

High quality insulating tubes for high frequency surgery

Safety and efficiency for minimally invasive procedures

Designed specifically for high frequency surgery (HF surgery), our custom-engineered, high performance plastic tubes are a critical component of safe and efficient minimally invasive surgical instruments. With over 50 years of experience as a plastics specialist and a broad portfolio of biocompatible materials, we offer custom-made insulation tubes for minimally invasive surgery instruments that meet the high demands of the application.

By using high performance plastics such as medical grade PEEK or PPSU, we replace the complex process chains associated with the use of metal components and insulating shrink tubing. Ensinger medical grade plastics are marked with the trade name abbreviation MT respectively MED for Compounds. Our comprehensive portfolio of Ensinger Medical Grade (MT, MED) plastics offers designers a wide range of options for developing innovative medical products with high levels of safety and functionality. In addition, our high level of manufacturing expertise enables us to customise insulation tubes to the exact diameter specified by the trocar. Other custom sizes are also available. High-heat plastic tubing for minimally invasive surgical tools meets the high demands of surgical instruments and offers additional benefits with its inherent insulating properties, high temperature resistance and resterilisability.

Insulating tubes from Ensinger: key components in minimally invasive instruments

Ensinger's insulating tubes offer an advanced solution by providing insulating properties, high levels of compatibility with sterilisation processes and precise dimensional tolerances, improving the safety and efficiency of minimally invasive surgery equipment. Insulating tubes are precision-manufactured components that fit seamlessly into minimally invasive surgical instruments. They are used to insulate the electrode and confine the electrical current to the desired surgical site and are typically used in conjunction with monopolar instruments. Our tubes are available in a range of diameters from Ø3 to Ø24 to suit different instrument sizes and applications.

Benefits of high temperature plastic insulation tubes for minimally invasive surgery tools

Electrical insulation

High heat resistance

By using high-performance plastics such as PEEK or PPSU, our insulating tubes have a high level of heat resistance, which is particularly important as the application of the tools generates heat due to the voltage, which the tubes must be able to withstand.

Sterilisability

A wide range of medical devices such as surgical instruments can be reused after intensive cleaning, disinfection and sterilisation. Ensinger Medical Grade (MED / MT) materials have good chemical resistance and excellent sterilisation resistance to common processes.

Low density

The use of our insulating tubes makes minimally invasive surgical instruments lighter, improving ergonomics and offering significant weight advantages over metal components.

Dimensional stability

Our precision-manufactured tubes maintain the integrity and precision of the instruments by retaining their dimensional stability even under the most demanding operating conditions.

Biocompatibility

Fitting to the trocar

Post processing options

Security of supply

Ensinger - Your Partner for Medical Components and Minimally Invasive Instruments

Ensinger is your reliable partner for medical components and minimally invasive instruments. With our many years of experience, comprehensive product portfolio and in-depth expertise, we support our customers in the development and manufacture of high-quality medical devices. We are available to discuss your individual requirements and find tailor-made solutions for your application.