Our online portal, TECAPART, offers you the opportunity to quickly and easily calculate and order plastic prototypes. Simply upload your CAD model and technical drawing to immediately receive a quote with prices and delivery times. We support you throughout your entire development process, from rapid CNC prototyping to series production.

Register now on TECAPART and start your CNC project with us in just a few minutes.

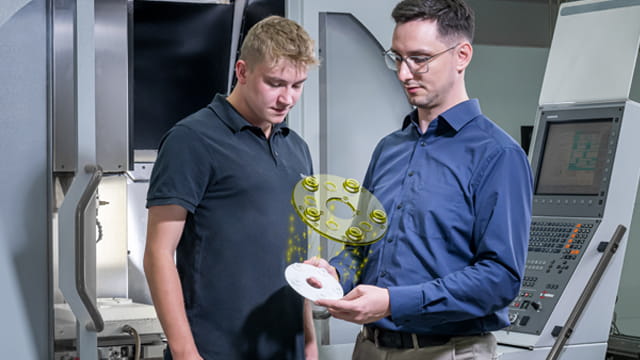

At Ensinger, you have access to a wide range of over 25 high-performance thermoplastics, as well as more than 100 modifications in the form of plates, rods and tubes, available in stock for CNC prototyping. These materials are characterised by their excellent mechanical properties and other specific advantages.