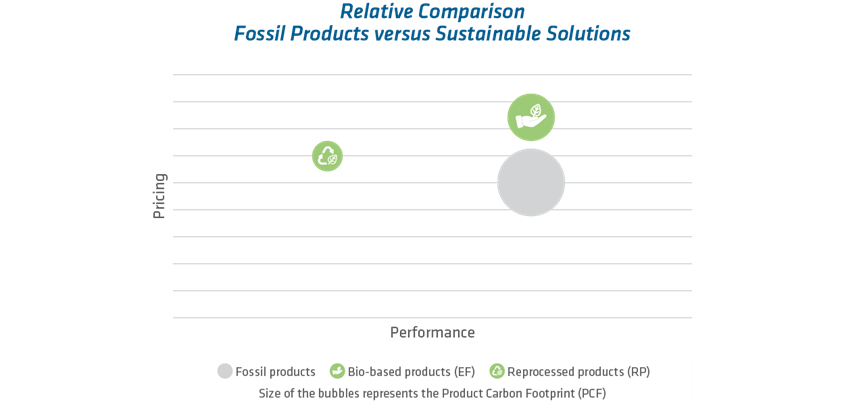

We introduce sustainable plastic solutions, showcasing a comprehensive approach with a significantly optimised carbon footprint.

As we aim worldwide to reduce green house gas emissions, a sustainable use of plastic is essential. Many still end up in thermal treatment instead of being reused. Our sustainable solutions aim to prevent linear use of finite resources and reduce the reliance on fossil raw material.

Our comprehensive approach accomplishes in two ways:

We offer products made from bio-based plastics derived from biological waste like wood by-products and organic waste or renewable resources. In addition, we provide reprocessed plastic products sourced from production left overs, utilizing mechanical reprocessing methods. Through these efforts, we aim to reduce the demand for new fossil-based resins and foster a more sustainable use of plastics.

Make your choice between our different environmentally friendly solutions:

Our special bio-based products replace fossil resources with products made from bio-based raw materials. Bio-based means that part of the raw material is organic, ideally derived from wood industry waste or organic waste (EF products).

We also offer polymers whose monomers are partly derived from renewable resources, but which do not compete with arable crops. Our biopolymers therefore have an optimised carbon footprint compared to their conventional counterparts.

The CO2 footprint of the bio-based stock materials can be found on the respective product pages in the PCF Statement.

Our mass-balanced bioplastics, which we call EF products, are made from biowaste.The manufacturing process of the bio-based plastics is the same as the fossil-based versions, ensuring comparable properties and colours with only minimal differences. Our bioplastics maintain comparable specifications and comply with industry standards.

Discover our EF products made from bio-based rods, tubes and plates!

Discover our RP products and reprocess fossil resources, by giving them a second life. The reprocessed stock shapes are sourced from the production left overs from customers and Ensinger subsidiaries, which are returned to Ensinger and carefully refurbished.

While the reprocessing may result in a slight reduction of properties compared to traditional fossil products and potential darkening, the environmental benefits of a significantly reduced footprint can often far outweigh this.

The CO2 footprint of the bio-based stock materials can be found on the respective product pages in the PCF Statement.

The stock shapes are available as reprocessed rods, tubes and plates.

Do you have any further questions or need support? Get in touch with us!