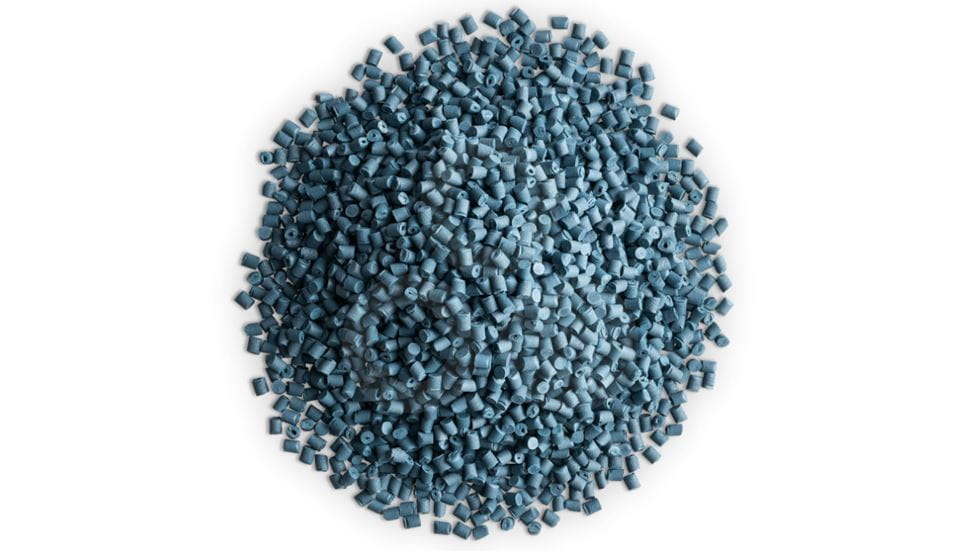

TECACOMP POM ID blue 1055303

POM-C compound for tribological applications in the food industry

TECACOMP POM ID blue is a functionally modified POM compound optimised for POM injection moulding. Based on a polyoxymethylene copolymer (POM-C), it was designed for applications with high requirements for temperature stability and detectability in food-related environments.

The material is characterised by favorable sliding and friction values, high dimensional stability, and strong mechanical performance, which remain constant across a temperature range from -50 °C to +100 °C. Short-term thermal loads up to 140 °C are also possible. Compared to unfilled POM granules, detectability has been enhanced through the addition of colouring and metal-based components. This allows abrasion or fragments of the POM plastic granules to be reliably detected by metal and X-ray systems.

The distinctive blue-gray POM resin is approved for direct food contact in accordance with FDA and EU Regulation 10/2011. Its contrasting colour ensures visual detectability in food environments, making the compound particularly suitable for components that must combine hygienic safety with reliable detection.

Typical applications for this POM granulate include conveyor technology, slide guides, rollers, stops, link chains, and molded parts used in processes such as hot filling or freeze drying. Thanks to its low water absorption, good chemical resistance, and hydrolysis resistance, it also performs reliably in humid or cleaning-intensive environments.

The material is characterised by favorable sliding and friction values, high dimensional stability, and strong mechanical performance, which remain constant across a temperature range from -50 °C to +100 °C. Short-term thermal loads up to 140 °C are also possible. Compared to unfilled POM granules, detectability has been enhanced through the addition of colouring and metal-based components. This allows abrasion or fragments of the POM plastic granules to be reliably detected by metal and X-ray systems.

The distinctive blue-gray POM resin is approved for direct food contact in accordance with FDA and EU Regulation 10/2011. Its contrasting colour ensures visual detectability in food environments, making the compound particularly suitable for components that must combine hygienic safety with reliable detection.

Typical applications for this POM granulate include conveyor technology, slide guides, rollers, stops, link chains, and molded parts used in processes such as hot filling or freeze drying. Thanks to its low water absorption, good chemical resistance, and hydrolysis resistance, it also performs reliably in humid or cleaning-intensive environments.