Tubes made from high performance polymer PEEK find their way into many different industries and applications, especially in the oil and gas or semiconductor industry. PEEK is often the choice of material due to its temperature, chemical and creep resistance combined with its thermal stability and compressive strength.

Required dimensions are as much of a driver as the application itself. Ensinger specialises in various processing methods to achieve the capability of producing PEEK pipes, tubes and rings for a wide range of dimensions. In our production facilities all over the world, we produce PEEK pipes and rings by using extrusion, compression moulding, rotational moulding process (often referred to as spin cast or spin moulding) and injection moulding. Compression moulding allows us to offer sizes with thicker cross sections and wall thicknesses, whereas spin molding provides the flexibility of offering billets that will perform in high temperature sealing applications, in a wide range of sizes that can be tailored to the customer’s needs. Moreover, we can customise the material blend for pipes and rings through adding suitable fillers and additives in addition to adjusting the OD and wall thicknesses to fit most oil & gas applications needs.

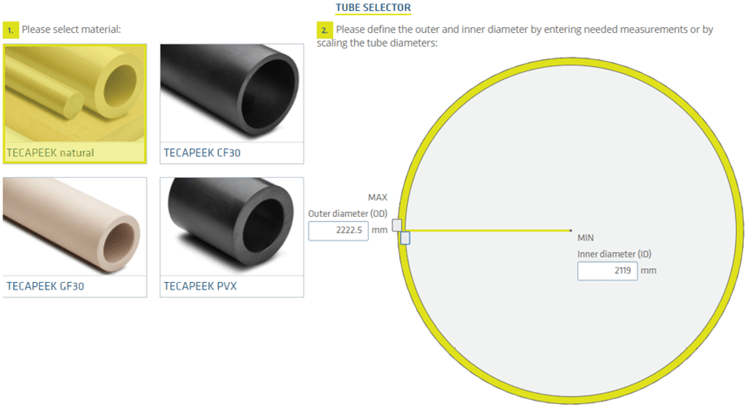

With almost 4000 different combinations of modification, production method and dimension, TECAPEEK offers the best diversity for the industries demand. Our PEEK pipes and PEEK rings are available with wall thicknesses between

5 to 180mm and outer diameters of up to 2200 mm. Lot sizes range from just one single piece e.g. for prototyping projects up to industrial size lots. With a wide range of tube sizes in stock, in addition to others being available on a custom order basis, our PEEK is a strong leader in the industry.

PEEK pipes, tubes and rings are available unfilled (TECAPEEK natural) and in the filled modifications, TECAPEEK GF30 natural (PEEK glass fibre reinforced) or TECAPEEK CF30 black (carbon filled PEEK). For special bearing applications that demand certain frictional properties, PEEK PVX (TECAPEEK PVX black) is the suitable choice.

A wide range of applications especially within the offshore sector, where high temperatures, high mechanical forces and resistance to aggressive chemicals are essential,

require a sour gas ageing test to confirm the qualification of the material for use in such harsh environments.

Our PEEK plastic, produced by the extrusion process, meets the strict requirements of NORSOK M-710 that is required for sour gas and other challenging environments throughout the natural gas and petroleum industry.

In this process a molten and homogenized thermoplastic polymer base (coming from an extrusion unit) is forced into a mould cavity by injection. During a defined cooling phase the polymer solidifies and flanges the geometry of the tool, then it is ejected by simply opening the tool.

Injection moulding is a method suitable for mid-high volume orders but best cost efficiency can be achieved with high volumes, especially as high tooling costs need to be considered if a non-standard shape is required. Injection moulding is best being used for rather small stock shape forms as large parts aren´t cost effective. Production speed itself is very high and lead times are short. Good variability of blends and modifications are available. Injection moulded materials offer the highest mechanical properties mainly with filled modifications.

Spin Moulding is an interesting method to produce rather big yet thin walled pipes and rings from polymers such as PEEK. Outer diameters of the final product are limited by the tool that is used. Approproiate amounts of polymer is then added into the heated tool while it spins around its roll-axis. Once the material melts it snuggles to the wall of the tool and builds up the desired wall thickness.

Spin moulding is suitable for low to medium order sizes where the MOQ can be one piece only. Unlike extrusion, this method is very flexible with regards to wall thickness and production speed is about five times faster compared to compression moulding. Due to the open inner diameter, voids, cracks and inclusions are practically eliminated. Spin moulded materials shows the lowest residual stress behaviour of all methods used in the Ensinger world, therefore, only short annealing times are needed. Also interesting is the very low waste accumulation and the suitability for near net shapes. Good variability of blends and modifications are available.