Ensinger produces PEEK thermoplastic as a standard semi-finished product for machining. The following shapes are possible:

Victrex® PEEK 450 or Syensqo KetaSpire® KT-820 (formerly Solvay) polymer can be used.

A great advantage of PEEK plastics is that the PEEK material properties can be adjusted to suit the application. Various PEEK modifications are available, such as fiber reinforced PEEK, PEEK with PTFE, conductive PEEK and others. You can choose the most suitable material depending on the application environment and field of use. We also offer special PEEK material types for medical, oil and gas, semiconductor, agriculture, food and aerospace applications.

The unfilled PEEK polymer shapes and its modifications are offered by Ensinger under the brand name TECAPEEK. The Ensinger TECAPEEK family includes the following modifications:

Fields of applications

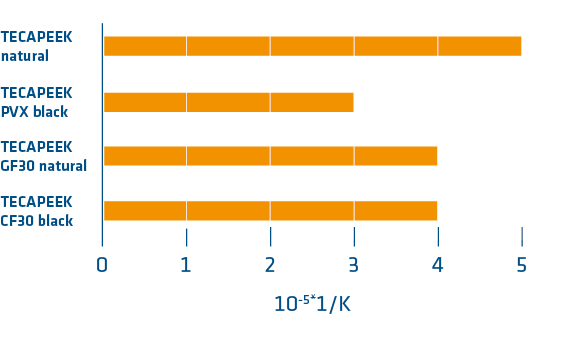

Reinforced with 30% glass or carbon fiber. PEEK reinforced grades exhibit higher stiffness and strength than unfilled PEEK materials. Improved heat resistance and hardness and a higher modulus of elasticity are also characteristics of carbon or glass filled PEEK.

Brand name |

E-Modulus (ISO 527) |

| TECAPEEK natural | 4200 MPa |

| TECAPEEK CF30 black | 6000 MPa |

| TECAPEEK GF30 natural | 6300 MPa |

Unreinforced PAEK with improved heat resistance and strength

A perfect choice when fiber-reinforced grades cannot be used. Compared to unfilled PEEK, they have a higher glass transition point and melting point. Other features include high strength, hardness, fatigue strength and dimensional stability at 150 to 200 °C.

Brand name |

Tg |

Tm |

| TECAPEEK natural | 150 °C | 341 °C |

| TECAPEEK HT black | 160 °C | 375 °C |

| TECAPEEK ST black | 165 °C | 384 °C |

TECAPEEK PVX black

TECAPEEK TF10 blue

Areas of applications

Ball bearing retainers, plain bearings, seals, rollers and guides etc.

TECAPEEK ELS nano black

TECAPEEK SD black

Both grades are optimized for CMP in semiconductor manufacturing, are compatible with various suspensions and feature excellent wear resistance.

TECAPEEK CMP natural

TECAPEEK SX natural

TECAPEEK CMF white

TECAPEEK MT

TECAPEEK MT CLASSIX™ white

TECATEC PEEK MT CW50 black

Contributes to improved safety in food production

TECAPEEK UD blue

TECAPEEK ID blue

PEEK is one of the best heat-resistant materials among high performance plastics. Even when used at 260 °C for 5000 hours, the strength is almost the same as in the initial state and excellent in thermal stability. PEEK has a long lifetime in the harshest environments.

PEEK has some of the best mechanical strength characteristics available among engineering plastics, including the following:

PEEK is also resistant to bending and, compressive stress, so it can also be used in situations where stability is required. In addition to standard PEEK, the following modified high-strength grades are available.

Unfilled PEEK natural is the most balanced material in high temperature environments, where non-lubricated sliding and non-contamination is required. Still, many applications call for special PEEK bearing grades as TECAPEEK PVX black, containing a multiple filler system (graphite, carbon fiber and PTFE), to fulfill a combination of requirements:

With this combination of criteria, this bearing grade material can be used in harsh environments of 100 to 300 °C. PEEK is used where conventional materials (POM, PA / Nylon etc.) would be beyond their limits. Because of these excellent sliding characteristics, they are used in gears, bearings, sliding bearings, and many other applications. In order to avoid thermal overload of a bearing, the resulting frictional heat should be dissipated as quickly as possible from the sliding surface of the bearing. The better the thermal conductivity of the part, the faster the heat is dissipated and overheating can be reduced. The fillers carbon fiber and graphite make TECAPEEK PVX black a superior bearing grade with improved thermal conductivity.

The sliding behavior always depends on the overall sliding system, and on parameters like sliding partner, load, sliding speed, surface roughness, temperature and so on.

Details: steel shaft Ø 4mm, sliding speeds from 0-22 mm/s, load of 30 N

Details: steel shaft Ø 4mm, sliding speeds from 0-22 mm/s, load of 30 N

PEEK is a highly pure material with very low VOC (volatile organic compound) content and low outgassing. In addition, it has a low water absorption of 0.03 % and can be used without worrying about outgassing in a vacuum environment like Aerospace.

The metal ion contamination is very low. This makes PEEK an excellent choice for the most stringent requirements in the semiconductor and solar industry, as well as for medical applications.

PEEK materials can comply to many standards and are used in various industries.

In any manufacturing environment, machine utilization is always a priority. Waterjet cutting parts might speed the part manufacturing process, yet still be limited by smaller plate sizes that require frequent change over. Ensinger's 1000mm wide PEEK plates offer additional machinable surface area that can increase part yield per plate by up to 30%.

Waste of material is unnecessary and expensive. Reduce your yield loss by selecting the perfect match for you. Choose from many different dimensions in stock and on request.

Sometimes it is best for a designer or machinist to try and look at things from a different perspective. Let our technical experts help you figure out the best way to nest your parts in the most appropriately sized shape from Ensinger's large selection of PEEK stock shapes.

Machined from TECAPEEK SM natural (spin moulded PEEK tube)

Machined from TECAPEEK natural and TECAPEEK PVX

Machined from TECAPEEK natural

Machined from TECAPEEK black

Machined from TECAPEEK CLASSIX™ white

Machined from TECATEC PEEK MT CW50 PL V01 natural (PEEK composite)

Other typical applications that are machined from PEEK plastics:

Electronical industry: PEEK insulators, connectors and wafer-carrier

Mechanical engineering: PEEK gear wheels, sliding elements, compressor- and pump-components, bushings, valves and rollers

Automotive industry: PEEK clutch and gearbox components and turbocharger impeller

Conveyor technics: PEEK guidances, strokes, rollers, grippers, and valves

Medical industry: PEEK parts for surgical instruments and short term implants

Food industry: PEEKvalves, PEEK valve seats, blenders, strippers, dosing systems and kneaders

Oil- and gas industry: PEEK drill heads, sealings and sensors