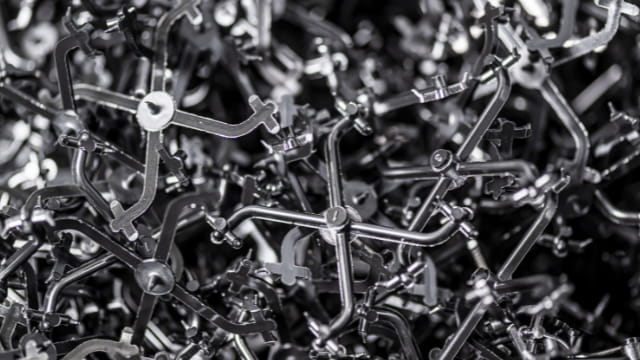

Injection molded parts made from high-performance plastics. Whether you need precise functional parts for medical technology, resilient components for aviation or complex geometries for mechanical engineering, we develop and manufacture custom injection molded parts from high-performance plastics that work where other materials reach their limits.

As an internationally positioned family-owned custom injection molding manufacturer with over 50 years of experience, we accompany your product idea from the initial sketch to series production – in close co-operation, with a wealth of engineering expertise and a clear goal: the optimal solution for your application.

We supply renowned OEMs with OEM injection molding solutions in a wide range of industries worldwide – including medical, aviation, industrial and automotive engineering – and have established industry-proven, standardized processes that ensure quality, traceability and efficiency along the entire value chain.

With our injection molding factories in the USA, Germany, China and Brazil, we stand for quality, customer proximity and reliable series production worldwide – no matter where your project starts.

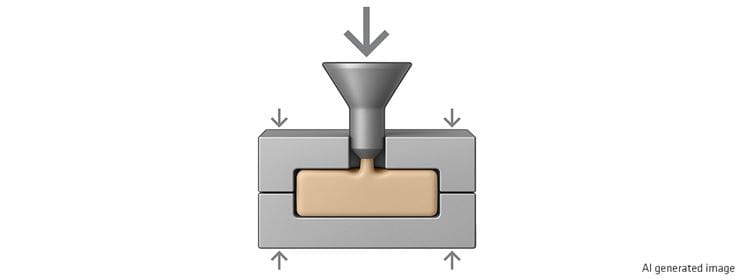

High-strength composite components are created by overmolding inserts made of metal or other materials – ideal for hybrid designs, thread inserts or electrical contacts.

Our team of experts will be happy to advise you on which process offers the best solution for your requirements.

Choosing the right plastic is crucial for the function, service life and manufacturability of a component. Ensinger processes a wide range of thermoplastic materials – from engineering plastics to high-performance polymers – precisely tailored to the requirements of your industry.

Thanks to our connection to Ensinger compounding, we also offer you the option of processing customer-specific modified materials – for maximum functionality and cost-effective series production. Among others, we use:

Are you looking for a development partner who is on the same wavelength as you – globally accessible and with a family-oriented mindset?

Let us work together to bring your component to series production.