Structural foam injection molding is an innovative injection technique used to produce microcellular plastic components with a reduced density and exceptional dimensional stability. Known by trade names such as MuCell®, this foaming injection molding process involves introducing a physical blowing agent – typically nitrogen or CO₂ – into the melt. This results in the formation of fine, evenly distributed microcells as the material is injected into the mold.

These microcellular injection molding techniques enable manufacturers to create lightweight and resilient components suitable for demanding industrial applications.

Modern machinery is adapted with a special injection unit to enable both compact and plastic foam molding using the same system. In injection MuCell systems, a blowing agent (like nitrogen) is introduced into the plasticized melt within the injection cylinder. The mix is then injected into the mold at high pressure, with the gas expanding in the melt during the injection phase.

The resulting internal foam pressure replaces traditional holding pressure, forming microscopically small cells that distribute throughout the part.

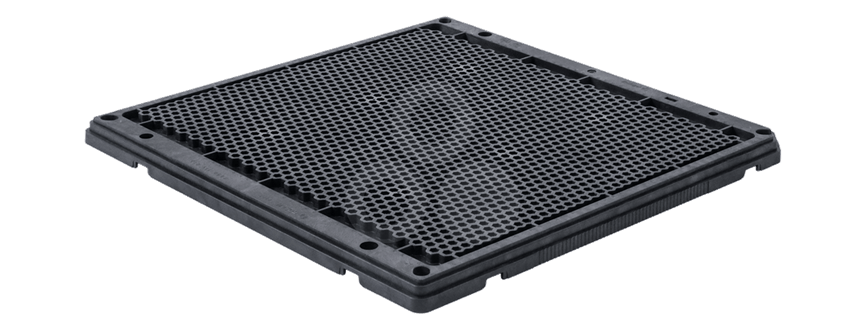

Once cooled, the foamed plastic component – consisting of a compact outer shell and a foamed core – is removed from the mold. The result is a lightweight, dimensionally stable part with high resilience.

The foam structure decreases the overall material density, making components up to 20% lighter while maintaining strength. With the right part design, wall thicknesses can be further reduced – particularly beneficial in aerospace, automotive and consumer goods sectors.

Warping is a common issue in injection molding. Structural foam injection eliminates the need for a holding pressure phase and enables stress-free solidification of the melt. This results in enhanced dimensional stability, reducing sink marks and delivering high-precision parts.

Whether referred to as Mu Cell, MuCell molding, or foam injection plastics, the principle behind plastic foam molding remains the same: achieve weight savings, reduce cycle times, and improve dimensional consistency.

Since 2023, Ensinger has been using structural foam injection molding, the more concrete MuCell process, at its site in Rottenburg-Ergenzingen to deliver high-performance and efficient solutions across all industries.