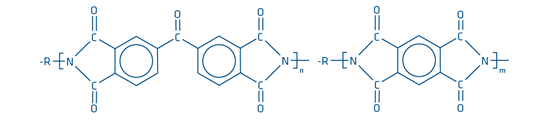

PI material is a non-melting high temperature polymer. PI polymers are characterised by an unusually complex property profile with many outstanding individual properties and are at the top of the materials pyramid. They are always used when conventional thermoplastics, ceramics or metals fail. This is because excellent temperature resistance, high mechanical strength and dimensional stability remain high even in continuous use and under mechanical stress.

With excellent friction and wear properties, even when unlubricated and under high pV loads, polyimide material is also ideal for demanding tribological applications. PI Polyimide applications can be found in many industries. High purity and low outgassing behaviour are additional advantages for applications in the aerospace, vacuum and semiconductor industries.

Polyimides are manufactured by polycondensation. Due to the high proportion of ring-shaped, mostly aromatic chain links and high molecular weights, polyimides are always infusible. They are therefore processed exclusively by sintering techniques.

Polyimides are often known under the brand name Vespel, but at Ensinger they are known under the trade name TECASINT.

Ensinger supplies sintered polyimides as semi-finished products in the following forms in many different dimensions.

Vespel® is a trademark of DuPont de Nemours, Inc.

Thermal and electrical insulating, best mechanical properties:

according to ESA regulations ECSS-Q-70-02

| Pur | 1011 | 2011 | 4011 | 4111 |

| 15 % MoS2 |

2391 |

Further polyimide material properties are:

made from TECASINT 6032 natural