PPS material is a semi crystalline, thermoplastic high temperature polymer and chemically known as polyphenylene sulphide. Due to its structure, PPS plastic is chemical and corrosion resistant and has very good mechanical strength. Its chemical resistance and tensile strength are maintained even at temperatures above 200 °C.

In addition, the properties of PPS are characterised by low water absorption, resistance to hot water and steam, and good dimensional stability. PPS polymers also have excellent dielectric and insulating properties that are stable under a wide range of conditions, as well as their inherent flame resistance.

PPS material manufacturers also offer polyphenylene sulphide polymer in reinforced form, such as PPS GF40, which is 40 % glass fibre reinforced. In addition, a variety of other PPS modifications are available.

PPS semi-finished plastic products are manufactured by Ensinger under the brand name TECATRON. Using the PPS extrusion process, we produce PPS plastic material in the form of

Through optimisation of the PPS manufacturing process, Ensinger succeeded in reducing internal stresses to levels that until now had not previously been achieved. The result is a new breed of PPS capable of meeting the market's highest application demands.

Low internal stress leads to less bending during PPS machining as well as less warpage. This is particularly important for parts made of PPS sheets that require high levels of flatness. In addition, this lower internal stress characteristic enables faster speeds and feeds. The need for intermittent post annealing steps between operations can also be significantly reduced. The result is faster part production and better yield, which considerably reduces costs.

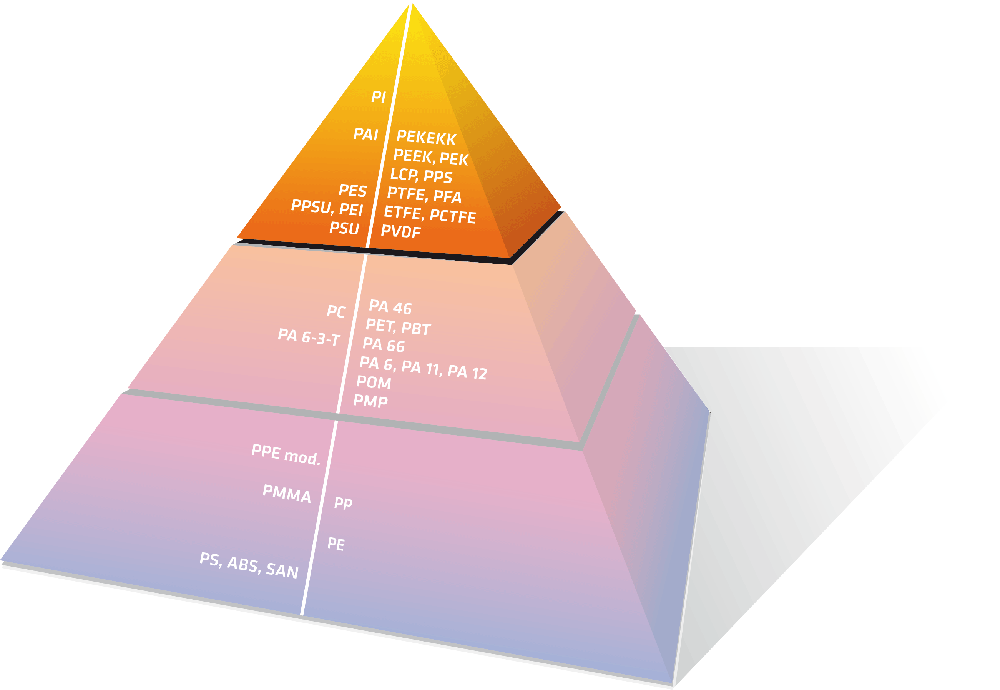

PPS thermoplastic belongs to the group of high temperature plastics and combines good long and short term thermal stability. It is also an excellent choice when it comes to a wide range of chemical resistance in harsh environments. Other remarkable PPS material properties are:

Click on the list below for detailed PPS plastic properties.

PPS plastic material has a very high thermal stability. Depending on the load, PPS can even be used long term at up to 230 °C. Such resistance is required in the automotive/engine compartment or in electronics, and PPS is often used for these applications. The thermal properties can be described in detail as follows:

Looking at the mechanical properties PPS is a very resistant polymer that is characterised by good dimensional stability even at temperatures above 200 °C. It has high tensile strength and high toughness. The tensile strength is further increased by the addition of glass fibres.

A material is considered to be dimensionally stable if it retains its original or essential dimension even when exposed to different temperatures, humidity, pressure or other loads. The basic behaviour is determined by the material properties. However, the manufacturing process also has a considerable influence on dimensional stability.

PPS plastic material is characterised by exceptional dimensional stability under thermal load. Only PEEK and PEI and especially the reinforced plastic grades can compete with PPS.

For plastic selection and design, it must generally be taken into account that the thermal expansion (CLTE) increases sharply in the range above the material-specific glass transition temperature. This essentially explains the differing performance behaviour, especially when comparing materials in the upper temperature range. In the case of PPS, this is around 97 °C.

Especially with regard to the thermal and mechanical properties, the comparison between PPS vs PEEK clearly favours PEEK. Although PPS offers a higher compressive strength compared to PEEK (at 5 % PEEK = 102 MPa vs. PPS =134 MPa). PEEK has a higher ductility (elongation at break PEEK = 15 % vs. PPS = 6.5 %). This results in a higher tensile strength (PEEK = 166 Mpa vs. PPS = 103 MPa) and a higher impact strength (notched Charpy PEEK = 4 kJ/m2 vs. PPS =2,6 kJ/m2) compared to unfilled PPS.

In addition, the lower ductility of PPS compared to PEEK affects the machining behaviour, which is characterised by less burr formation and shorter chips, but a higher risk of cracking.

For some applications, requiring machining operations to realise very delicate structures or micro-holes, PPS can lead to better results than PEEK.

In general, both PEEK and PPS have very good dimensional stability in terms of water absorption and thermal expansion. PPS shows slightly lower water absorption, while PEEK shows slightly lower levels of thermal expansion. While the CLTE of PPS is relatively low up to 100 °C (with 6*10-5/K), the CLTE increases steeply (up to 11*10-5/K at 100~150 °C) in environments above the glass transition temperature.

In addition to the advantages of PEEK having higher ductility, strength and temperature resistance compared to PPS, another advantage of PEEK is its better wear resistance. The data below shows a comparative wear test of different CMP retaining rings.

The advantages of PEEK over PPS are reflected in the comparative costs – PEEK being the more expensive choice. Therefore, PPS plastic is a good alternative especially when the material properties clearly exceed the requirements. In most cases, the lower-cost PPS alternative is then the better choice.

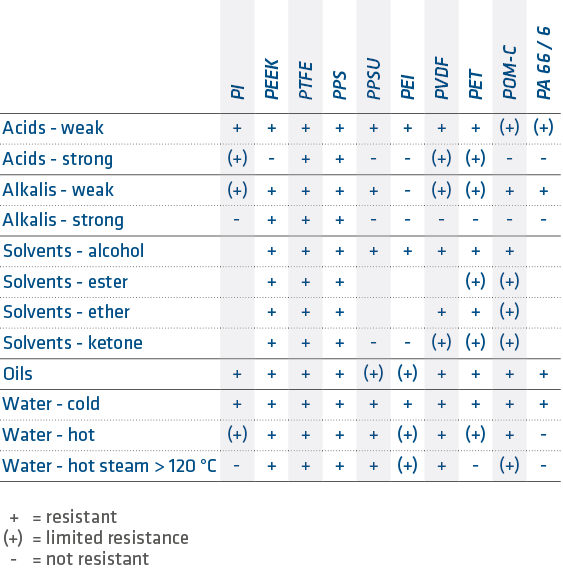

In addition to the over-engineering aspect, PPS material does have one decisive advantage: it has a broader range of chemical resistance than PEEK - only PTFE can top it in this respect.

Semicon industry: CMP retaining rings, Clamp rings, semiconductor fabrication equipment parts, IC test sockets

Electronic industry: PPS connectors, contact rails, heat shields, LCD manufacturing equipment, inspection fixtures for PCB, FPC, and IC package substrate

Automotive industry: "under the hood", fuel and brake systems

Medical industry: Parts for surgical instruments

Mechanical engineering: PPS gears, valves, compressor and pump-parts, slide bearings, chain guides and base plates

Chemical industry: PPS valves, taps, bushings, pumps, nozzles, tubes and rollers