The use of food-grade plastics that meet the most stringent specifications of the U.S. Food and Drug Administration (FDA) and European food contact regulations is an important requirement for food processing companies. For the Chinese market, Chinese food regulations must also be observed. As a processor of thermoplastics, Ensinger offers a wide range of solutions for corresponding applications. We offer many products from our standard portfolio of thermoplastics with the corresponding approvals for food contact. These products meet the special requirements of food technology in terms of safety and performance.

Ensinger issues product-specific food contact suitability certificates for its compatible materials. These certificates refer to FDA approval for raw materials, compliance with Regulation 1935/2004/EU, 10/2011/EU (specific measures for plastics) and 2023/2006/EU on good manufacturing practice (GMP) for materials and articles intended to come into contact with food. For the Chinese food market we offer certificates according to the Chinese GB standards

GB 4806.1-2016 as well as GB 4806.6-2016 (positive list for plastics) and GB 9685-2016 (for additives).

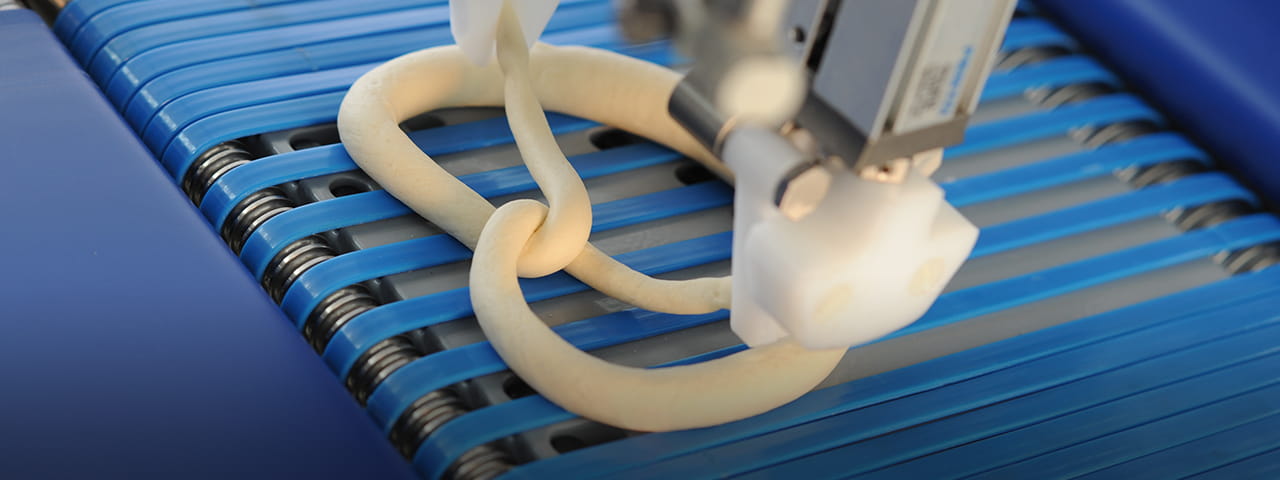

Thanks to their light weight and ease of processing, food contact plastics can replace metals in a wide range of applications, such as in plants and equipment for meat, fish, and poultry processing, as well as for dairy, bakery, and confectionery production. Food contact materials from Ensinger can improve production, speed and safety in the manufacturing process.

We also offer special plastics for the most common detection methods. As an alternative to conventional plastics, our portfolio includes blue materials for optical detection as well as plastics exhibiting multiple detective traits. These include our blue detectable products that are also metal and X-ray-detectable for direct food contact applications. We offer all these products as standard. This increases safety during processing and reduces costs.

Our technical department will be happy to assist you in selecting the most suitable materials and appropriate processing methods for your food application. This also includes the development of new materials.

Ensinger`s plastic materials designed for food industry are manufactured in compliance with Reg. (EU) No 10/2011 and FDA approval for raw material. Find out more:

Thanks to a specific traceability method Ensinger is able to determine and trace the complete process chain of its semi-finished materials. Find out more:

To ensure that products cannot be confused or mistaken, a product code is imprinted on them which contains the product name, article number and production batch.