Ensinger is PPSU manufacturer and supplies PPSU material as standard stock shapes, as well as in the form of PPSU filament, compounds and profiles. In addition, Ensinger offers the service of contract compounding.

Due to the PPSU material properties, the processing spectrum into finished parts is highly diverse.

Here, Ensinger can serve a broad range from prototypes from machining and injection moulded components. Ensinger is a specialist in PPSU when it comes to certified production in accordance with ISO 13485 standards in the area of machined parts.

All Radel® plastic modifications are sold and distributed under the brand name TECASON P. Ensinger manufactures standard stock shapes for machining using Radel® PPSU polymer in the following shapes:

Our PPSU stock shape portfolio offers a wide range of colours and various types suitable for medical applications. An overview of our TECASON products including the entire colour range is available in our portfolio. The Ensinger TECASON P family offers the following PPSU modifications:

Radel® is a registered trademark of Syensqo (formerly Solvay).

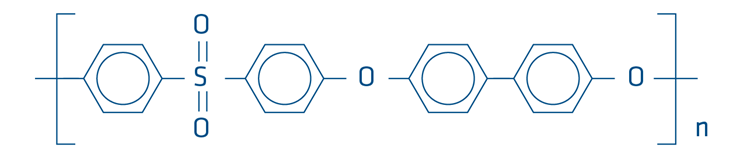

Properties of PPSU:

Medical: test implants/artificial joints for hip, knee, shoulder, handle of medical equipment

Biopharma: Measuring instruments