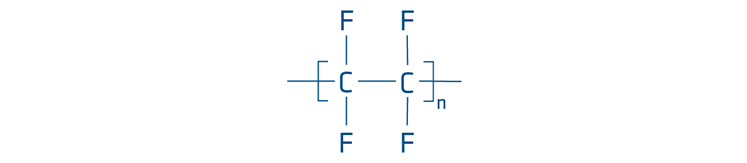

PTFE material (with the chemical name polytetrafluoroethylene, commonly referred to as Teflon® plastic) is a semi-crystalline fluoropolymer with many unique properties. This fluoropolymer offers exceptionally high thermal stability, chemical resistance, and corrosion resistance, as well as a high melting point (-200 to 260 °C, briefly also up to 300 °C).

In addition, PTFE products have excellent sliding properties, excellent electrical resistance and a non-stick surface. In contrast to other plastics, however, they have low mechanical strength and a high specific density. With these qualities, PTFE plastic is commonly manufactured into rollers, seals, and seal rings. To improve the mechanical properties, the PTFE polymer can be reinforced with additives such as glass fibers, carbon, bronze or even with polyimide.

PTFE specifications: