High temperature IC Test Sockets

High-Temperature Integrated Circuit Test Sockets TECASINT 4011 and TECASINT 4111

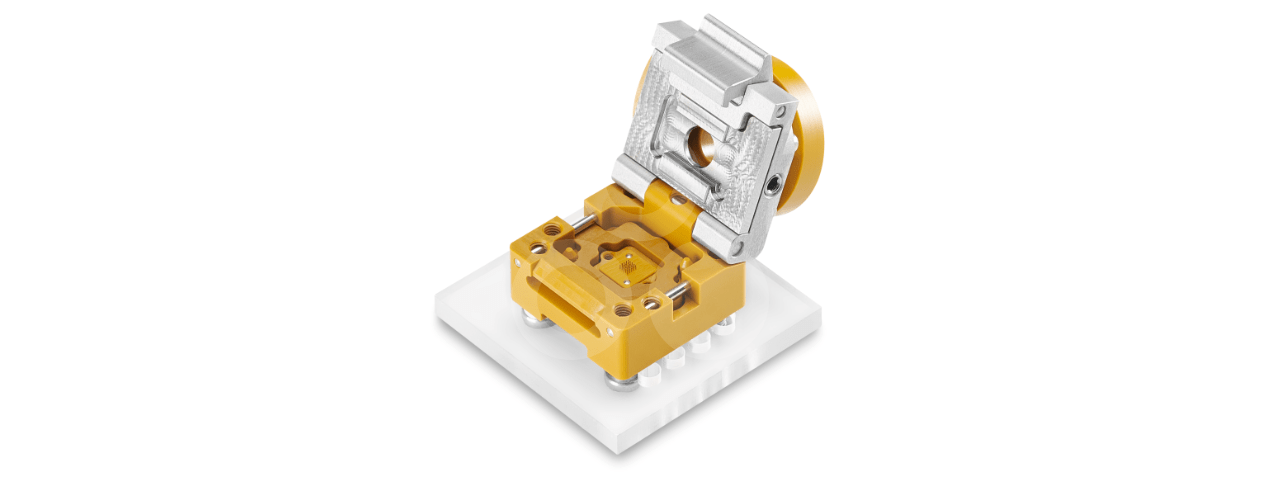

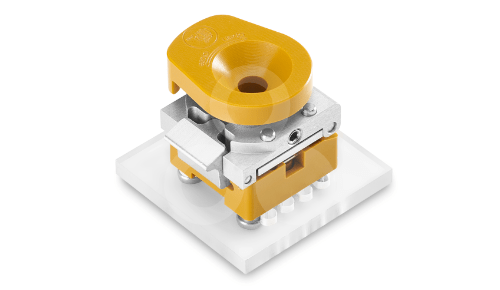

In the microchip manufacturing process it is important to test the chips under various conditions to ensure specific functionalities as well as durability. Different test sockets are used to test numerous microchips, as specified by integrated circuit designers. As several types of high performance and engineering plastics are used to manufacture test sockets, the demand for plastic materials continues to grow rapidly.

Withstanding harsh testing cycles

The IC test socket body or housing is typically made of PEEK, PEI, LCP or PAI for moderate test temperature ranges between -55 ℃ to 180 ℃, while for higher temperature requirements materials like polyimide continue to be utilised. Ensinger’s unfilled polyimide TECASINT 4011 and TECASINT 4111 provide significantly higher thermal resistance than conventional test socket materials, enabling dimensional stability, strength, and stiffness to remain high even above 260 ℃. TECASINT 4111 offers the highest stiffness and the lowest CLTE among unfilled test socket plastics, as well as the lowest water absorption among the TECASINT series. TECASINT 4011 is the more economical alternative compared to TECASINT 4111 and offers a unique combination of toughness and stiffness enabling excellent micro machinability.

Coefficient of thermal expansion 23 - 200°C

E modulus at -200 - 500°C

Resisting deformation under high pressure and temperatures

Complex socket designs challenge conventional socket materials. For example, the market is trending towards thinner cross sections of test socket contact plates, so that the materials must provide higher rigidity to avoid deformations during testing. With flexural modulus up to 6100 MPa for unfilled TECASINT 4111, it provides maximum stiffness at high temperatures for optimum bending resistance under pressure. The following data shows that strength and stiffness is kept on a high level in high temperature environments. In addition, the sintering process technology significantly lowers internal stress levels compared to extruded and injection molded parts, enabling minimum warpage during machining to meet the tightest flatness tolerances.

Flexural strength after thermal ageing at 340 °C

Tensile Strength 23/260 °C

Tensile Modulus at 23/260 °C

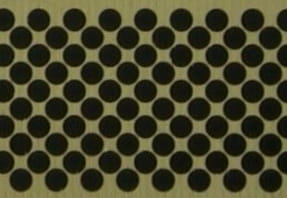

Excellent micro hole machinability and accuracy field

Continuous decrease in pitch spacing and pin hole sizes require test socket designers to choose materials with enhanced micro-machinability and dimensional stability. TECASINT 4011 offers excellent machinability of fine features with extremely low burring. Compared to fiber-reinforced plastics which commonly result in limited machining accuracy due to drill bit deflections, the unfilled TECASINT series enables significantly improved hole position accuracy. The right balance of stiffness and ductility, combined with a very low internal stress level, enables TECASINT 4011 to realize extremely precise hole placement while keeping burring and cracking to a minimum.

TECASINT 4011 machining example of 0,18 mm holes without deburring

Complex socket designs can often lead to long and costly machining times. TECASINT 4011 offers very low internal stress, drill bit wearing, burring, and cracking, having a considerable impact on yield improvement and fabrication costs and time reductions. For some special applications, test sockets are manufactured using laser drilling to further reduce fabrication costs. TECASINT having no melting point has proven to be suitable for realizing clean micro holes via laser drilling.

Maintaining tightest tolerances

With increasing complexity and miniaturization of test sockets, another challenge is the dimensional stability during fabrication and after prolonged use. TECASINT 4011 and TECASINT 4111 provide considerably reduced water absorption compared to industry standard polyimide or PAI, so that the small pitch arrays of high-end test sockets remain within tolerances.

Water absorption

The perfect match

Both TECASINT 4011 and TECASINT 4111 are proven materials for high temperature IC test sockets due to their high stiffness and dimensional stability at high temperatures. TECASINT 4011 is the fitting material for high temperature test sockets requiring excellent micro-machinability with high hole position accuracy as well as minimum burr formation and cracking, TECASINT 4111 is the fitting material for test sockets requiring very high rigidity and dimensional stability under high temperatures.