Cell holders made from reprocessed PEEK in the battery module

An application example for sustainable High-Performance plastics

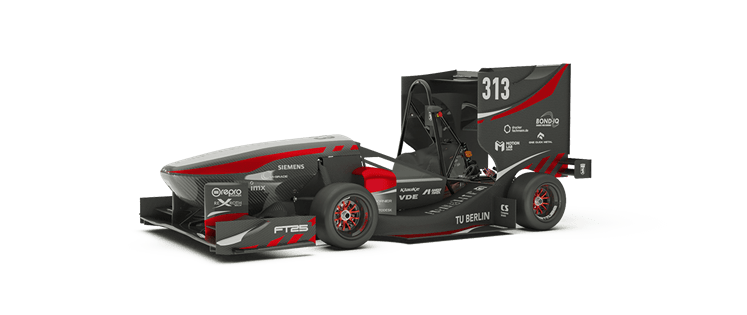

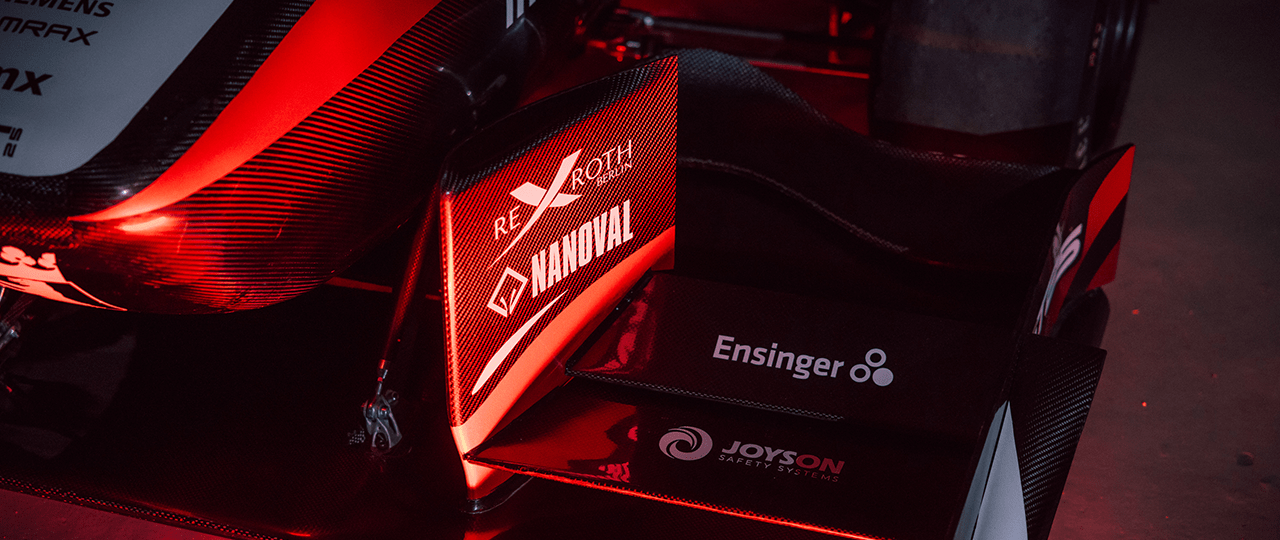

For the construction of a high-voltage battery module, a Formula Student team relied on TECAPEEK RP natural. The reprocessed PEEK high-performance plastic was used in the production of cell holders and impressed with its combination of thermal resistance, mechanical stability, and excellent machinability. At the same time, the material contributed to CO₂ reduction, an aspect that is becoming increasingly important in the development environment.

Lightweight, stability, and precise: TECAPEEK RP natural under extreme conditions

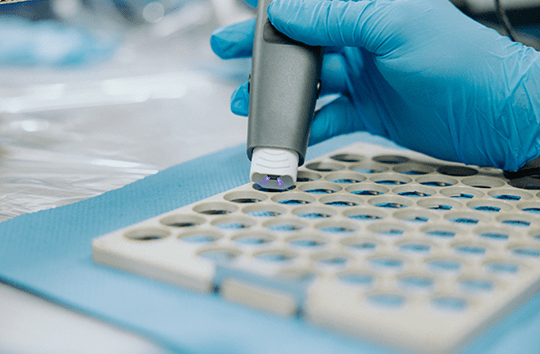

The battery of a Formula Student race car is one of the most safety-critical and heavily stressed components in the vehicle. Around 400 cells must be precisely fixed, electrically insulated, and built in with flame resistance, all while keeping the weight as low as possible. With TECAPEEK RP natural, a material was provided that reliably met these requirements. The students manufactured highly precise cell holders from the PEEK stock shapes and achieved a weight reduction of around 30% compared to component solutions in previous car models.

Technical advantages

The use of TECAPEEK RP natural offered numerous design and processing benefits:

- High mechanical strength for secure fixation of the cells

- Thermal stability for operation in high-temperature environments

- Flame resistance in accordance with UL94 V-0

- Excellent machinability for complex, detailed geometries

- Isotropic material properties for consistent performance in all directions

Where geometries could not be milled, the PEEK filament TECAFIL PEEK VX natural was additionally used in 3D printing for example, in functional connecting elements. This made it possible to realise designs that are difficult to achieve with conventional machining and at the same time, distribute screw loads more effectively.

Sustainability in focus: Reprocessed PEEK with a CO₂ advantage

TECAPEEK RP natural is a reprocessed PEEK high-performance plastic produced from internal, single-type material returns. The material offers solid technical performance for a wide range of applications while providing a reduced CO₂ footprint. Especially in projects where functionality must be combined with resource efficiency, TECAPEEK RP natural creates new opportunities as demonstrated by the TU Berlin example.

Conclusion: Technical solutions with a focus on sustainability

The Formula Student project shows that with TECAPEEK RP natural, technical performance and sustainable material use can go hand in hand. The reprocessed PEEK offers all the advantages of a high-performance engineering plastic and fits perfectly into modern development processes that balance performance with environmental impact. We are proud to have supported the next generation of engineers with our material and to set new benchmarks together for sustainable applications in high-end environments.