“Can you see plastic on x-ray?” This is an often asked question the answer to which is that generally, engineering and high-performance plastics do not show up well on x-ray or fluoroscopic displays, unless they have been modified in some way to make them more opaque than the surrounding substrate. This characteristic is important for applications in both the medical and food industries, and Ensinger has developed innovative solutions for both.

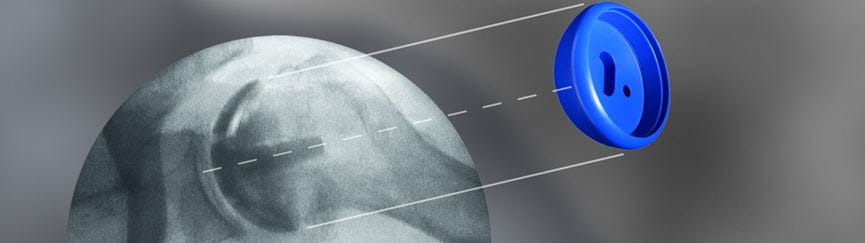

With its X-ray opaque XRO materials, Ensinger meets the challenging demands of minimally invasive and image-controlled surgery while also offering additional safety and security during surgical operations. X-ray plastics are used for a variety of instruments, such as tools and trial sizes, where clear visibility of components is advantageous.

A contrast medium added to the standard TECAPEEK MT and TECASON P MT lines permits clear visibility of components under fluoroscopy and X-ray radiation. It provides the surgeon with a precise picture of their instruments or of orthopedic trial implants during image controlled procedures.

Ensinger offers an X-ray opaque filament, TECAFIL PPSU MT XRO blue, as well as the x-ray opaque semi finished TECAPEEK MT XRO (PEEK) and TECASON P MT XRO (PPSU). These plastics are manufactured in many standard colours, produced to suit the customer requirements. This allows greater flexibility when designing your applications by allowing users to be able to easily distinguish between different instruments and sizes or allowing for differentiation of competitor's products by colour branding.

TECAPEEK MT XRO is a medical grade PEEK, TECASON P MT XRO and TECAFIL PPSU MT XRO are medical grade PPSU. All are modified to better visibility and radiography.

As in-line x-ray technology and its associated costs have improved, producers in the food industry have begun to embrace the technology as a reliable method for alerting production workers to the presence of unwanted particulate matter during food quality inspection.

Some compounds and shapes from Ensinger have not only optical and metal detective characteristics, but also have the ability to be picked up by typical in-line x-ray detection systems that are being deployed in food production facilities for quality inspection purposes. These ultra-detectable (vision, x-ray and inductive) products have been proven to be valuable material choices to equipment designers looking for the most versatile engineering x-ray plastic solutions.

To complement our products, we offer a comprehensive range of processing methods and products as well as customised profiles and tubes to meet your individual requirements for your finished or semi-finished part.

For detailed information, please contact us via our contact form.