Ensinger is a global supplier of extruded polyamide material, also known as nylon plastic. The most common extruded nylon is polyamide 66, which offers a balanced combination of performance and cost. Nylon was the first engineering plastic and is used in a wide range of applications from electronics, marine and automotive industries to fibers for carpet manufacturing. Extruded nylon 66 material has excellent wear resistance and low friction properties while exhibiting very good temperature, chemical and impact properties.

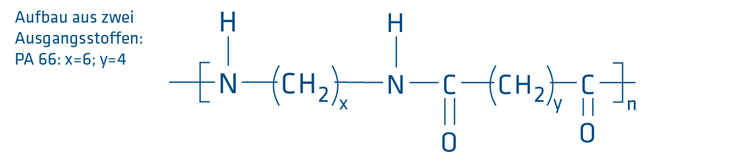

Other extruded polyamide types are PA 6 and PA 12. These nylon plastic types vary in properties due to differences in molecular structure. These differences particularly affect the mechanical properties and moisture absorption of the PA. Ensinger also offers several options for fillers that further enhance a material's properties. These options include glass-filled nylon (glass-filled polyamide), carbon-filled Nylon (carbon-filled polyamide), and internally lubricated nylon (internally lubricated polyamide).

Ensinger is a supplier of extruded polyamide stock shapes and offers over 150 different dimensions of PA 66 material in the form of

Polyamide plastic modifications are manufactured by Ensinger under the tradename TECAMID. Certain grades of nylon 66 contain fiber fillers that increase the capabilities of TECAMID 66 accordingly. For example, fiber filled polyamide modifications have higher compressive strength than unfilled nylon types. The ease of machining nylon 6 and nylon 66 makes TECAMID suitable for many applications in a variety of industries.

The Ensinger TECAMID family includes the following nylon modifications:

Extruded polyamide offers: