The oil and gas industry demands high temperature, high pressure (HTHP), high mechanical strength and chemical resistance materials, suitable for the most extreme environments. Modern technical plastics have a major contribution to make towards improving existing solutions in the oil and gas industry due to state-of-the-art materials that offer a greater range of benefits. Ensinger has invested heavily in research and development to find innovative solutions to new technical challenges. With expertise in developing and manufacturing high-performance and engineering plastic materials, Ensinger’s product portfolio has been enhanced to meet the specific requirements of the oil and gas industry, suitable for a wide range of applications. With extensive experience in the oil and gas sector, Ensinger works closely with customers to achieve the optimum solution to suit their application's requirements. Technical material experts can provide customers with a qualified material recommendation, which can be confirmed by practical testing.

Current systems in place in the oil and gas sector largely use modern materials such as Polyimide, PTFE, PA 6 C, PPS, PAI and PEEK. In addition to this, Ensinger’s PEEK products are tested in accordance with NORSOK M-710, which verifies the material's resistance to the severe conditions of the environment it will be exposed to.

The oil and natural gas industry is typically broken down into three categories: upstream, midstream, and downstream. Oil exploration, extraction, and production are the main activities of upstream oil companies.

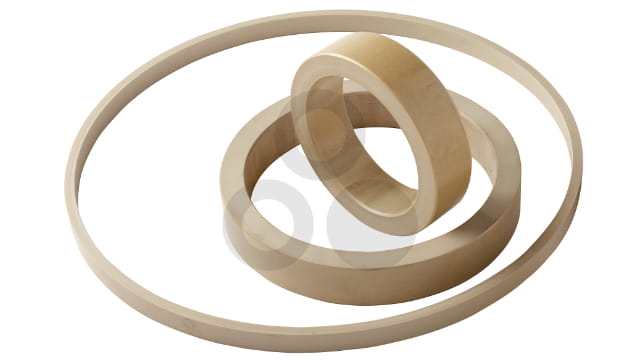

Ensinger supplies a vast range of products that are used in upstream and gas exploration, including blowout preventers (BOP), seal components, electrical connectors, back up rings, valve seats, housings, high pressure packing, seals rings, steam seals, etc.

The midstream segment of the oil and natural gas industry refers to anything required to transport and store crude oil and natural gas before they are refined and processed into fuels and key elements needed to make a very long list of products used in everyday activities. Midstream also includes pipelines and all the infrastructure needed to move these resources long distances, such as pumping stations, compressors, tank trucks, rail tank cars and more.

Downstream industry includes everything involved in refining and transporting petroleum products to end users. This industry process transports many products related to our everyday necessities such as diesel, natural gas, gasoline, heating oil, lubricants, asphalt, insecticides, medicines, and propane as well as sub-products such as chemicals that will be the base material for things like fabrics, and plastics.

Ensinger also has extensive experience in the manufacture of PEEK tube, offering a wide range of standard tube sizes and wall thicknesses. Custom sizes are also available, with the ability to adapt to large dimensions. Alongside this, the material blend can be customised by adding fillers and additives to suit the needs of specific applications. A variety of applications in the oil and gas industry can benefit from Ensinger’s PEEK tubes due to their outstanding properties.

Our PEEK shapes products are tested according to NORSOK M-710.

With our many years of experience, we are the expert for your customised application in the gas and oil industry. We can advise you on the selection of the right material, the right processing technology and the design of the end product. As a full-service plastics supplier, we have a fully integrated value chain, offering everything from compounds, stock shapes or filaments to finished products from a single source.

Ensinger’s PEEK products are able to achieve compliance for use in highly demanding oil and gas applications in accordance with NORSOK M-710, Edition 3.