While both methods can provide high-quality parts, it’s important to understand how each process converts raw materials into a component that is ready for secondary operations or shipping.

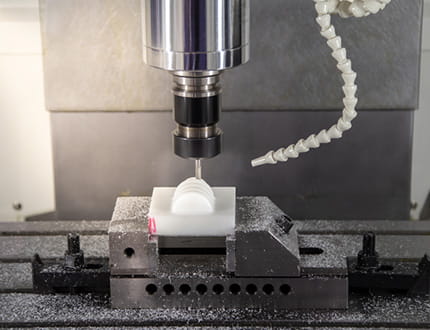

CNC stands for computer numerical control. CNC machines used for plastic processing are typically advanced multi-axis systems that are computer-controlled for precision and accuracy. Machining is considered a subtractive manufacturing method because the machine, whether mill, lathe, or router, removes material from a stock shape or injection molded blank. The number of axes depends on the machine and its function. But generally speaking, the more axes a machine has, the more complex part it can produce with reduced manual handling.

The shape of the part determines which machine, or machines, is used. A CNC lathe, which rotates the workpiece against the cutting tools to make a shape, is ideal for symmetrical objects like spheres, cylinders, or cones and can also create features such as drill holes, bores, and threads. With a mill, the cutting tool rotates around the workpiece, allowing it to make complex shapes. Routers operate on a three-axis spindle at a higher speed than a mill.

Comparatively, injection molding is a formative technology. The process involves melting a polymer and injecting the molten plastic into a mold, where it cools and solidifies to form the desired part. In addition to traditional molding, overmolding and insert molding are options for more complex products. Overmolding is when one plastic material is molded over another. Insert molding is when plastic is molded over non-plastic parts, such as a soft-touch handle on a metal scalpel.

Other differences that are important to consider are design, cost and volume, and materials:The best advice is to consult a plastic manufacturer experienced with injection molding and CNC machining plastics if you are unsure which process is best for you.

At Ensinger, we have a long-time reputation for being plastics experts. We have in-house engineers with the tools and skills to ensure your product is designed for manufacturability and functionality. We combine material and process expertise, whether CNC machining or injection molding, to provide high-quality parts that consistently meet your expectations. Contact us for a consultation on your next project.