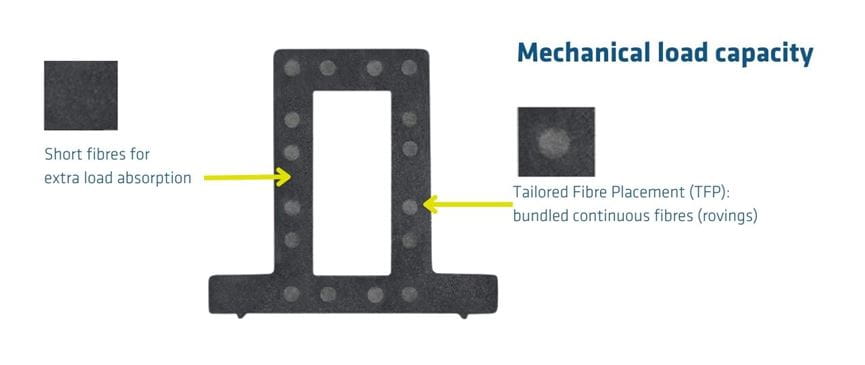

Using continuous fibers to optimize mechanical properties.

Optimal mechanical properties at a low weight.

Beneficial properties of thermoplastic materials:

Reduce your CO2 footprint with continuous fiber reinforced profiles manufactured with thermoplastic pultrusion:

Material |

Density |

Flexural strength |

Modulus of elasticity |

| [g/cm2] | [MPa] | [GPa] | |

|

Auminium EN AW-6060 T66 |

2,7 | 215 | 69.500 |

|

Pultruded profile made of polyester resin |

1,8 | 250 | 28.000 |

|

Extruded profile made of unreinforced PA |

1,1 | 100 | 2.900 |

|

Extruded profile made of PA with 40 vol% short glass fibers |

1,7 | 240 | 15.500 |

| Pultruded profile made of PA with 47 vol% glass fiber (UD) rovings | 1,8 | 400 | 37.500 |