Ensinger Machined Parts is not only committed to providing first-class machining services, but goes far beyond that. We consult with our customers prior to the start of a project and use our wide range of services to achieve the best possible results for our customers.

Detailed information below.

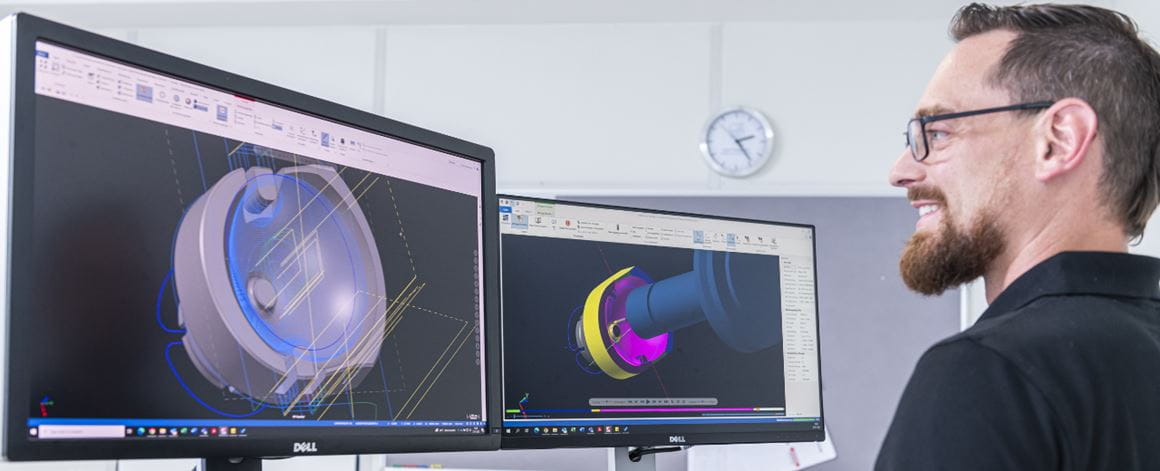

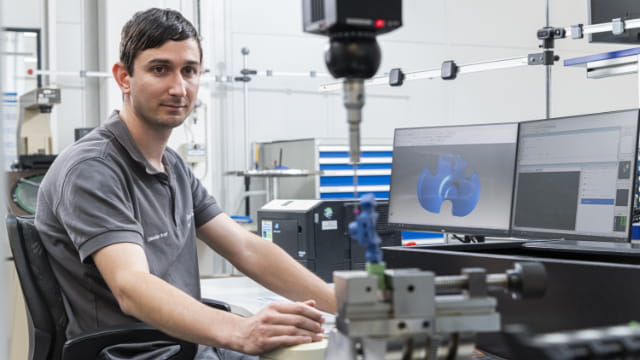

After extensive planning, programming and preparation, we machine the components on our modern machinery. It is important to Ensinger to always be up to date and we invest regularly in our machining centers. This constant development enables us to respond to the increasingly specific requirements of individual industries.

Detailed information below.

Our modern machinery is permanently kept up to date through continuous investment. Through this constant improvement, the possibilities for machining on the CNC machining centres are expanding more and more. Highly complex components, which used to be classically turned and then milled, can now be manufactured in a single operation. Driven tools and milling swivel heads in the machining centres create these conditions and are used by us.

Furthermore, we manufacture components with unusual length-to-diameter ratios using the sliding head turning process, which sets us apart from the traditional market in CNC plastics machining and allows us to offer an even broader range of manufacturing services.

A majority of our turning centres are equipped with automatic bar loaders and loading robots are also used successfully, which results in a high degree of utilisation of the systems.

These factors and our qualified specialist staff make Ensinger the ideal partner for CNC turning.

The amount of further processing possibilities for the precision parts at Ensinger is almost limitless. Deburring and surface finishing are among the standard processes, while labeling, assembly and various cleaning processes are also possible. In direct connection with the validated cleaning process, we offer our customers the option of assembly and packaging in our qualified clean room.

Detailed information below.

Due to complex part geometries or specific material properties, a 100 % burr-free CNC production cannot always be ensured. In this case, our wide range of reworking options is available. From manual deburring by our qualified personnel (sometimes under a microscope), to deburring using dry ice, to blasting with various media such as glass beads, nutshells or high-grade corundum, we have many options at our disposal.

The latter variants are not only used for deburring the parts, but also serve perfectly in the area of surface treatment in addition to the vibratory grinding (trowalising) we offer. Typical turning and milling marks can thus be reduced to a minimum so that the surface quality can withstand the high demands of a wide range of industries.

As your one-stop shop, we naturally also offer the option of assembling components and systems. Typical assembly work includes pressing in and screwing in pins, bearings or threaded sleeves, screwing together several components or joining by means of bonding. Ultrasonic welding of components is also one of the possible processes of our assembly team. Additionally, we carry out functional tests defined by you and document them.

If required, assembly work can also be carried out in the clean room.