In the field of custom plastic profiles, we combine experience and innovation to produce plastic profiles that meet your exact requirements. In doing so, we do not only rely on over 50 years of experience in the field of high-performance thermoplastics, specially developed and established plastic profile production processes and in-depth technical know-how. The constantly changing demands and requirements of our customers also leads to the continuous further development of our processes and products. We do not settle for the standard, instead, we search for new ways in order to find the right solution for your project.

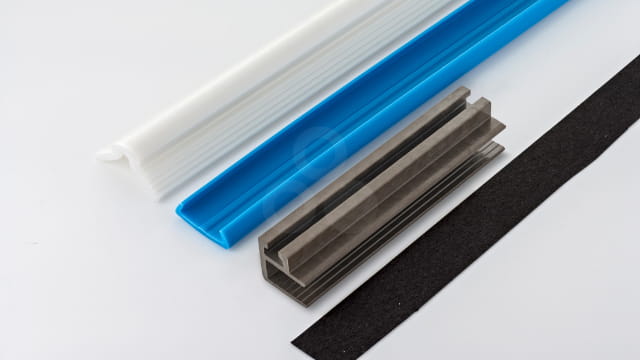

We offer a wide range of geometries and wall thicknesses. Even with complex geometries and tight tolerances, we offer the highest quality made in Germany.

Depending on the customer's requirements, we can also process the profiles using in-line or off-line processes.

Where metals and aluminium reach their limits, high-performance plastic profiles offer new solutions. Our short and continuous fibre reinforced profiles not only offer comparable mechanical properties - they also contribute to a reduced CO2 footprint over their entire life cycle.