Orthopaedic trauma internal fixation systems

These target systems, also known as "target arms" or "target devices", are subject to high demands. This starts with the forces exerted by the surgical technique on the system and therefore on the material. For example, they must be able to withstand rough handling as well as falls without plastic deformation. X-ray transparency and physiological harmlessness (biocompatibility) are also of fundamental importance. High targeting accuracy, even after many sterilisation cycles, together with very good resistance to chemical cleaning, make the target arms a high-tech product. Metals and epoxy resins have many disadvantages and it is difficult to meet all these requirements.

Composites hold the key to the future

We have a dedicated facility to meet these challenges and have been successfully manufacturing composite and stainless steel aiming devices and other surgical instruments for over 20 years. In addition to materials and manufacturing expertise, the site has an ISO 13485 quality management system and is FDA registered. In addition, Ensinger Medical's sales engineers assist customers in designing target devices to meet production requirements without compromising aesthetics. This Design For Manufacturing (DFM) approach reduces development time and costs for our customers.

Read more about composite machining for medical devices here.

For other target manufacturers looking for innovative solutions, we offer the TECATEC MT portfolio of highly suitable composite materials, which we also use in our own facilities.

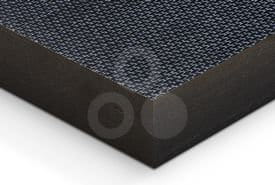

In order for the holes for the screws to fix the plate or nail in the bone to be drilled with very high positioning accuracy, the insertion guides must not be subject to any plastic deformation. Accordingly, TECATEC PEEK MT CW50 black is characterised by very high mechanical parameters, especially in terms of specific strength and stiffness.

Our TECATEC PEEK MT CW50 black is also radio-transparent, allowing unrestricted x-ray imaging of the surgical area despite the target device. The material meets the specified requirements of the biocompatibility testing according to standard ISO 10993-1, -4, -5, -18 for contact of up to 24 hours with skin and tissue and, if applicable, indirect contact with blood.

The high glass transition temperature of 143°C, the low water absorption of the material and the very good chemical resistance result in very good sterilisation resistance and high thermal dimensional stability. As a result, high accuracy is maintained even after many hot steam sterilisation cycles.

Take a closer look here! By zooming and rotating, you can have a detailed look at the target arm.