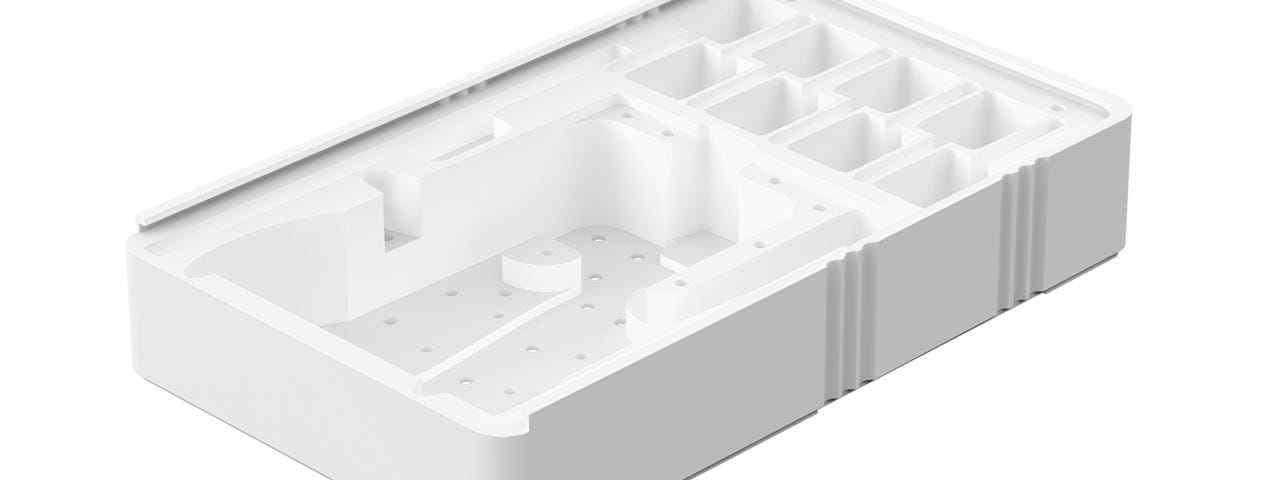

Surgical caddies

Containers for the transport and storage of surgical instruments

Trays and caddies for transporting and storing surgical instruments as well as screws and additional implants are subject to stringent requirements:

- Simple transport throughout the sterilisation procedure

- Long product service life

- User-friendliness thanks to the option of labelling or marking

- Flexible design for simple and secure storage of instruments, screws or additional implants

The optimum material for surgical caddies

Taking the requirements outlined above into consideration, the materials TECAPRO MT (PP – polypropylene) and TECASON P MT (PPSU – polyphenylsulphone) are an ideal solution. Our medical grade (MT) plastics offer manufacturers and equippers of trays and caddies excellent raw materials for the production of light, durable and easy-to-handle transport containers. For example: TECAPRO MT and TECASON P MT boast a lower specific weight than conventional materials like aluminum and stainless steel. In addition, they offer excellent resilience to chemicals including conventional pH cleaners. Unlike other conventional materials, the specially modified plastic TECAPRO MT also has excellent dimensional stability.

The excellent resistance to chemicals, including pH cleaners, and to conventional steam sterilisation in autoclaves means that the surface of the plastics remains pristine, in contrast to metals and aluminum, where the anodised surface coating can be damaged or even eroded completely in the worst-case scenario. This results in trays and caddies with longer service lives compared to competing products made of metal.

Trays and caddies made of TECASON P MT and TECAPRO MT are absolutely biocompatible. In comparison to trays and caddies manufactured from aluminum this results in a significant increase in physiological safety. For example: there is no anodised protective layer, which can be damaged by abrasion and impacts, subsequently leading to biocompatibility issues.

benefits

Service life of instruments extended thanks to increased protection

The use of thermoplastic medical grade plastics like TECAPRO MT and TECASON P MT offers instruments better protection from blunting compared to caddies made of aluminum. As a result, cutting edges stay sharp and can be used for longer. This reduces maintenance and cuts replacement costs.

Improved handling

Their low specific weight makes trays and caddies made of TECAPRO MT and TECASON P MT easy to handle and more convenient to employ in routine clinical practice. Their low weight also makes it possible for them to accept larger quantities of instruments and implants. All in all, true added value for your customers.

Optimised design saves you money

The well-balanced properties of the plastics make it possible to create designs with considerably fewer individual components compared to trays and caddies made of metal, which require the production of additional parts such as brackets. As such, the use of our materials makes logistics and assembly simpler and more cost-effective for you.

Design and labelling for differentiation

The ability to write on TECASON P MT and TECAPRO MT with a laser makes it possible to label the implants contained and sizes individually, or even apply your own corporate brand. In the special case of TECAPRO MT, laser writing creates a striking color contrast in white, which opens up a wide range of design possibilities and does not have the same disadvantage as aluminum that the laser layer on the anodised aluminum can wear off during reprocessing.

Our experts are happy to inform and advise our customers about laser applications personally.

Cost-efficiency thanks to just-in-time delivery

The high number of TECAPRO MT and TECASON P MT items kept in stock at all times means they can always be delivered to customers quickly and efficiently. We are your go-to partner for just-in-time production.

Recommended plastics for surgical caddies

TECASON P MT is also available in the following colors: