Alternative to aluminium LED heat sinks made from thermal conductive PPS

Thermal development in LED lights need heat sinks

LED lights are being used more and more as substitutes for conventional light bulbs and neon lights in the aerospace industry. Though LED lights generate much less heat than conventional systems, they nevertheless need heat sinks because the heat will concentrate under the LEDs. Therefore, to avoid this potential fire risk the heat must be dissipated.

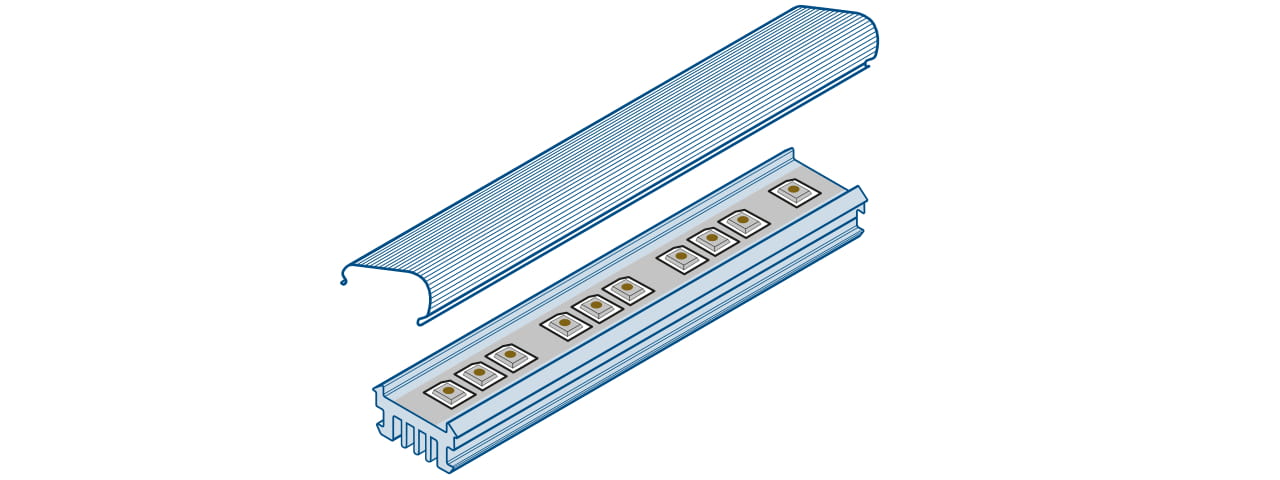

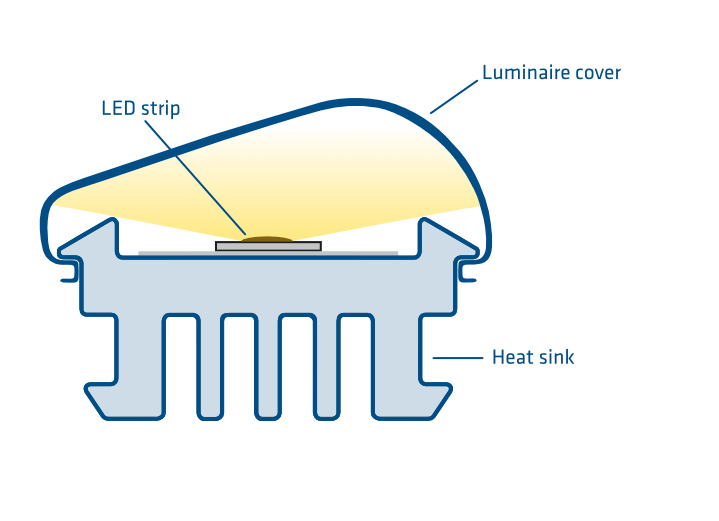

In LED lights which are constructed in rows, the LED chips are set on circuit boards. These LED strips are mounted on a heat sink to dissipate the targeted heat effectively. Typically a heat sinks holding profile is produced from aluminium, however, in many cases plastic profiles can replace the aluminium counterparts as the LED chips have a comparatively low heat emission as well as an advantage through weight reduction and life cycle costs.

Metallic holdings need grounding

In metal heat sinks electric voltages may occur, which increases the risk of short circuits and thus the risk of fire. For this reason, in aviation, all metal brackets with electrical plug connections must be grounded. This means more work on the material side, because often a fastening screw with the necessary corrosion protection measures is not sufficient. If the metallic mountings are located on non-conductive structures, an additional grounding cable is required, which must of course also be fixed. These grounding measures cause additional weight due to the material used and the necessary corrosion protection. In addition, valuable installation space is required.

Planning, installation and documentation steps are also necessary for the use of such grounding cables: An entry in the electrical diagram is necessary, a resistance measurement must be defined for each grounding cable in the test plan and the contact resistance of each earth connection must be recorded. At regular intervals, the grounding systems are maintained and tested. This results in high life cycle costs for the airlines.

Precision profiles made from PPS replace Aluminium

A good substitute for aluminium in heat sinks are high-performance plastics with thermal and, if necessary, static dissipative properties. In the lighting units described here, the heat sink is made of PPS, and an extruded profile made of polycarbonate is used for the lamp covers.

The development and production of the profiles for the heat sink and the luminaire cover is carried out by the Ensinger "Profiles & Tubes" division. Close cooperation and the exchange of knowledge within the Ensinger divisions leads to rapid development results.

Excellent thermal and static dissipation

Not only the base polymer PPS used here, but also other base polymers can be made thermally conductive, electrically insulating or electrically conductive with certain fillers. The thermal conductivity of our materials can reach 10 W/(m-K) for some of our electrically insulating materials by using additional fillers. Where electrically conductive polymers can be tolerated, a thermal conductivity approaching 25/w can be offered. Ensinger Compounds for example develops formulations to optimise thermal or electrical conductivity or insulation. As few fillers as possible are used in order to not negatively influence the properties of the base materials.

Plastics are much lighter than aluminium

Flammability classification

Flame retardant plastics such as flame-retardant polycarbonate or polyamide (TECAMID 6 FRT) are preferred for heat sinks used in aviation. The materials used for the heat sink described here, PPS for the heat sink and PC for the luminaire cover, also comply with flammability class UL94 V-0.

High chemical resistance

PPS and for example TECAMID 6 FRT or polycarbonate display excellent corrosion and chemical resistance to the media used in aviation.

Freedom in design

Extruded and, if required, further processed plastic profiles offer a high degree of design freedom in component design dimensioning, which reduces manufacturing and assembly costs.

Complete systems from one source

Ensinger is able to offer heat sinks and luminaire covers as complete systems. In doing so, we can draw on the experience of experts from the various Ensinger divisions at home and globally.

- Advice on material & possible design

- Choice of compounds

- Feasibility assessment profiles

- Machining or other further processing

Contact

You can reach us by our contact form, by email at [obfemailstart]YWVyb3NwYWNlQGVuc2luZ2VycGxhc3RpY3MuY29t[obfemailend] or by phone +49 7032 819 643.