The calculation is based on a uniform industry standard set by the EPSM (Engineering Polymer Shapes for Machining Association), which Ensinger has adopted together with other leading stock shape manufacturers. This means that our CO2 values are not only traceable, but also comparable across the industry.

The calculation is based on comprehensive primary data from our production and reliable background data (e.g., from the EcoInvent database). The calculation follows the international DIN EN ISO 14040 series of standards and the IPCC GWP 100a standard.

You can find out more about the calculation methodology on our environment page:

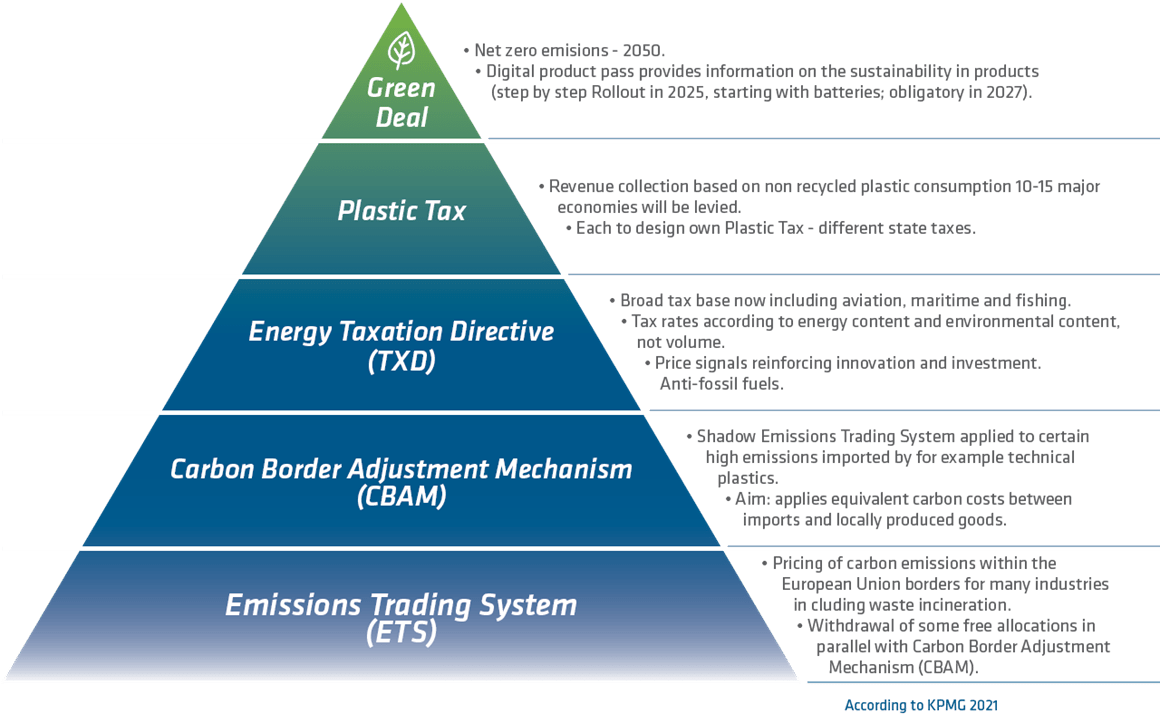

In order to move towards sustainability, it is essential to work on reducing the footprint of our products. Due to the chemical nature of high-temperature plastics, it is difficult to change the processing steps or the required processing temperatures without affecting the quality. For this reason, we are converting our production to renewable energies, investing in our machinery to make production more efficient and looking for sustainable plastic alternatives that have a smaller ecological footprint. In the sustainability report, you will always find the latest figures and projects that bring us one step closer to net zero.

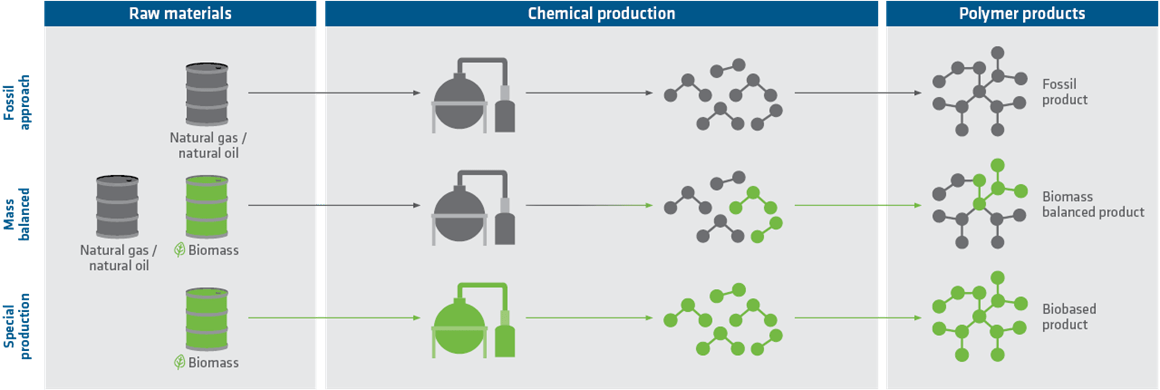

Biomass balanced refers to the use of organic raw materials, derived from kitchen or agricultural waste, wood industry residues or renewable raw materials for instance. Through a chemical process, these materials are transformed into bio-based monomers, which is then blended with fossil monomers and processed through the same chemical reactions into polymers as pure fossil products. The resulting mixture, comprising both bio and fossil monomers, is classified as biomass balanced.

The distinction between biomass balanced and mass balanced lies in the source materials. Biomass balanced products use organic raw materials, while mass balanced products may utilize chemically recycled plastic monomers, among other sources, blended with fossil monomers during production.