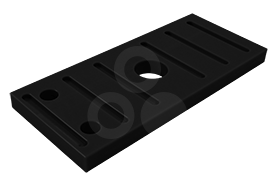

TECAGLIDE black

Cast nylon with extremely good sliding and wear properties

TECAGLIDE black is a PA plastic which is manufactured in a casting process. This cast nylon is characterized by extremely good sliding and wear properties due to the addition of proprietary solid lubricants. Because of the combination of lubricity and high mechanical load properties, TECAGLIDE is considered one of the optimal solutions in our portfolio for sliding applications at high speeds, especially when it comes to the desire to manage friction while enhancing wear properties. As an example, this PA6 plastic can be used in mechanical engineering as plain bearings, guide rails or gear wheels just to name a few.

PA plastic TECAGLIDE is electrically insulating, extremely resistant to most oils and has a high degree of ductility and toughness. In addition, no external lubrication is required for most applications due to the material's unique property and performance profile. TECAGLIDE black is available from stock in all dimensions as plates and rods.

PA plastic TECAGLIDE is electrically insulating, extremely resistant to most oils and has a high degree of ductility and toughness. In addition, no external lubrication is required for most applications due to the material's unique property and performance profile. TECAGLIDE black is available from stock in all dimensions as plates and rods.